Fuel system

|

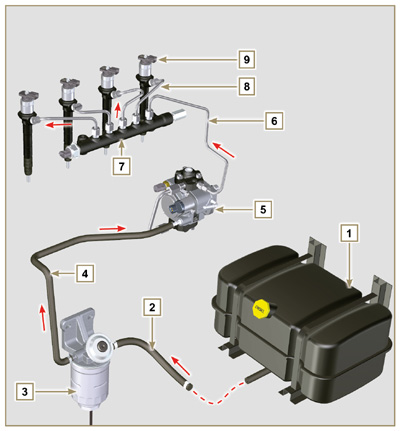

2.9.1 Injection circuit (pressure 2000 bar) (Fig 2.4)

Important Important

|

|||||||||||||||||||||||||||||

|

The fuel supply system is under low pressure from fuel tank 1 to the high-pressure fuel injection pump 5.

NOTE: The representation of fuel tank is purely indicative. Component not necessarily supplied by KOHLER.

|

Fig 2.4 |

||||||||||||||||||||

|

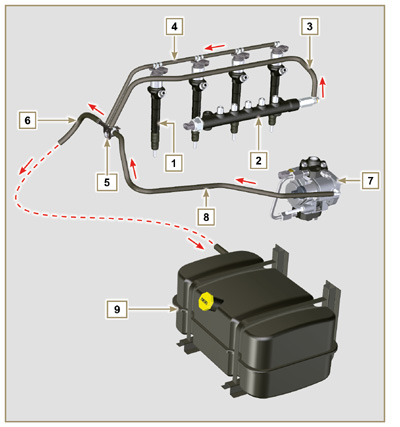

2.9.2 Fuel return circuit

NOTE: The representation of fuel tank is purely indicative. Component not necessarily supplied by KOHLER.

|

Fig 2.5 |

|

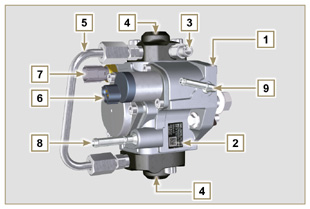

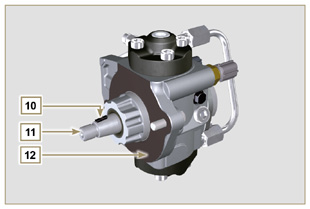

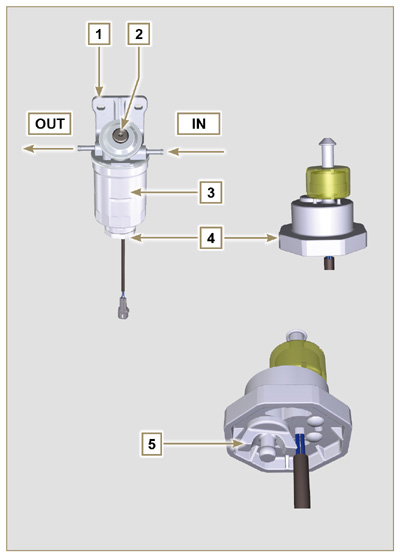

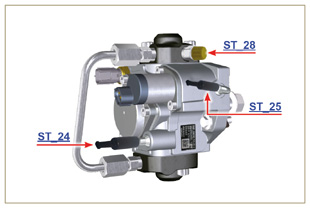

2.9.3 High-pressure injection pump (2000 bar)

Important Important

NOTE: In the event of leakage from the high pressure circuit do not intervene when the engine is running, but turn it off and wait 5 - 10 minutes before checking the leakage.

The inlet pressure to the high pressure pump must be between 300 mbar (suction pump without electric supply) and 200 mbar (with electric pump power) to the high pressure rail. The high pressure pump is operated via the pump control gear and sends high pressure fuel to the common rail.

NOTE: The supply tube (on union 8) and fuel return (on union 9), have different diameters.

|

Fig 2.6  Fig 2.7 |

|

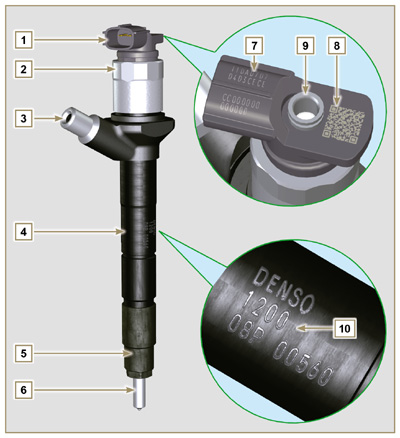

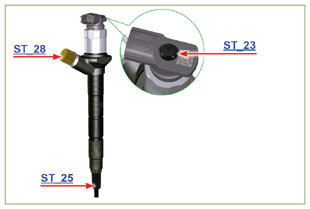

2.9.4 Electronic injector

Important Important

|

Fig 2.8 Tab 2.16

|

||||||||||||||||||||||

|

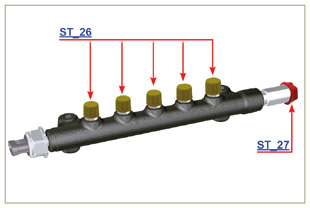

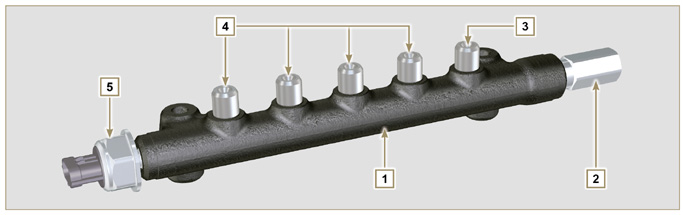

2.9.5 Common Rail

The pressure sensor 5 measures the pressure of the fuel in the Common Rail.

Important Important

|

|||||||||||||||||||||||

|

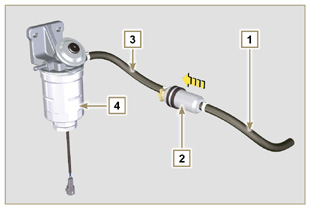

2.9.6 Fuel filter

Tab 2.19

|

Fig 2.10 |

| 2.9.7 Electric fuel pump (optional) When the electric fuel pump is installed in a diesel engine, one must:

Tab 2.20

|

Fig 2.11 |

||||||||||

|

2.9.8 Guards for fuel injection circuit components

Cap protections must be accurately washed after use and placed back in their housing (ST_40).

Important Important

|

Fig 2.13  Fig 2.14  Fig 2.15 |

Loading

Loading