=

Search

Electric system

|

2.13.1 ECU input and output signals diagram

|

|||||||||||||||||||||||||||||||||||||||

|

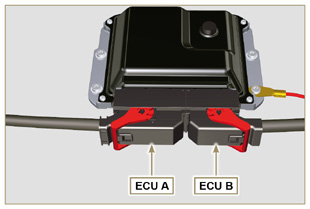

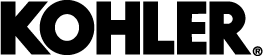

2.13.2 Control unit (ECU)

Important Important

|

2.13.2.1 Technical features

|

||||||||||||||||||||||||||||||||||||||

|

Fig 2.32 - Fig 2.33

Tab. 2.35

|

|||||||||||||||||||||||||||||||||||||||

|

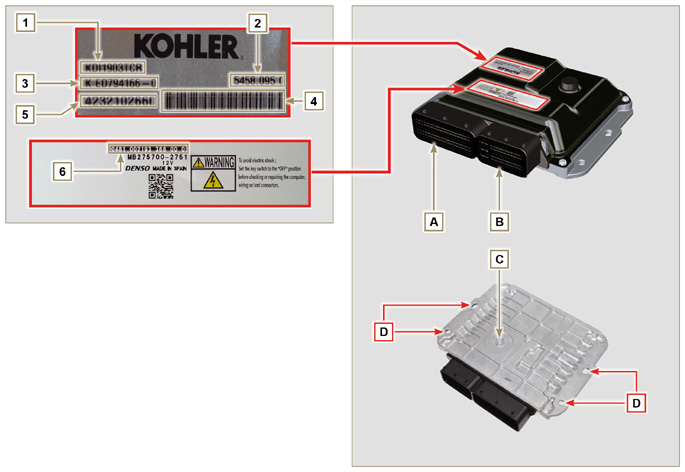

2.13.3 Engine electrical wiring

Fig 2.34 |

|||||||||||||||||||||||||||||||||||||||

|

Tab. 2.36

|

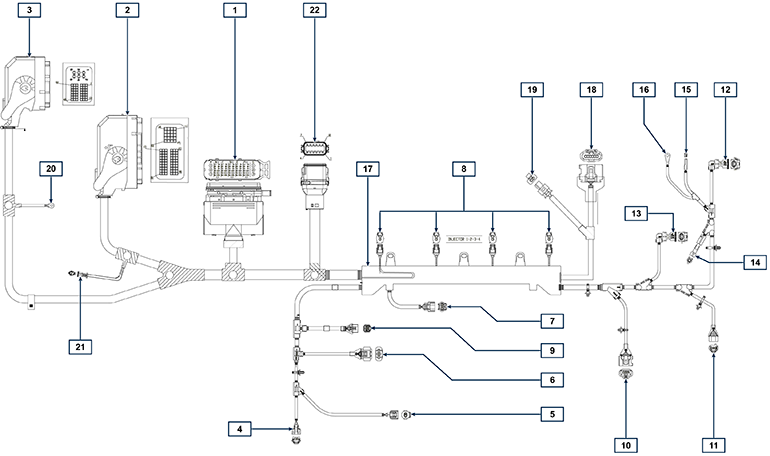

Fig 2.34a  Fig 2.34b |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOTE: Click by side to play the procedure. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

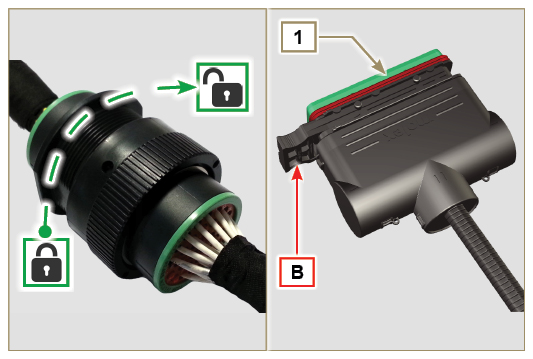

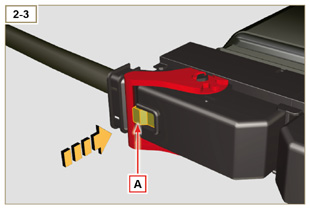

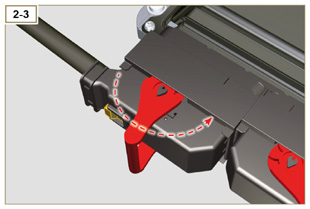

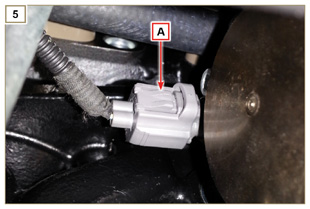

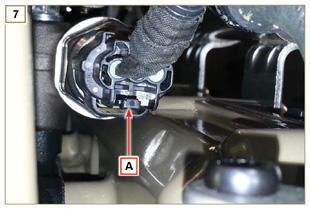

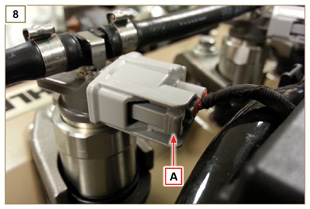

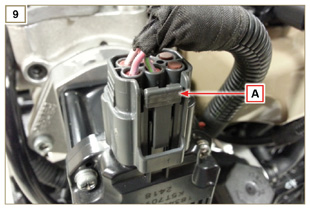

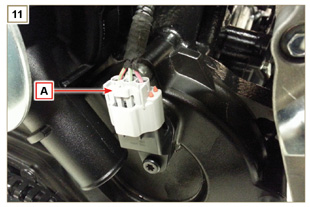

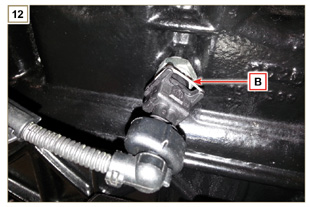

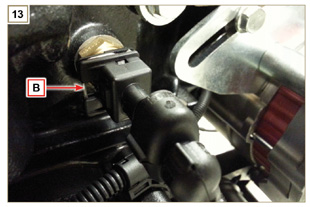

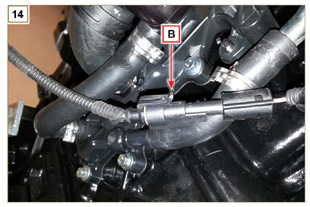

| 2.13.3.1 Wiring disconnection All sensor connectors and electronic control devices are sealed. The connectors must be disconnected by means of pressure on tabs A or unblock the retainers B, as illustrated from Fig. 2.34c to Fig. 2.34r. |

Fig 2.34c |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34d |

Fig 2.34e |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34f |

Fig 2.34g |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34h |

Fig 2.34i |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34l |

Fig 2.34m |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34n |

Fig 2.34o |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34p |

Fig 2.34q |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fig 2.34r |

Loading

Loading