Danger Danger

- Highly carcinogenic material!

- The dust contained inside the DPF is particularly fine and therefore classified as highly dangerous to living beings.

- Before proceeding to any operation, wear:

dust mask

gloves

goggles

- Do not allow any other operator who is not equipped with the above mentioned protective equipment to approach.

|

|

- Obtain a new replacement KIT for the DPF filter or a replacement KIT with regenerated DPF filter from your spare parts service.

Important Important

- Before disassembling/assembling any sensors, see Par. 2.17.5 and 2.17.6

- See service letter 710023.

- Always replace the seal P upon every assembly.

- During disassembly, do not expose the DPF to the surrounding environment for a long time and store it in a sealed bag as soon as possible.

- During disassembly operations, avoid using electric screwdrivers as vibrations could release the dust inside the DPF

- Do not try to clean the DPF

- Do not blow with compressed air

- Do not release the DPF or the dust contained in it in the environment

- Dispose of the DPF only in authorised centres

- Perform the operations indicated in point 1 of Par. 11.8.

- Open the package of the DPF replacement KIT, taking care not to damage it.

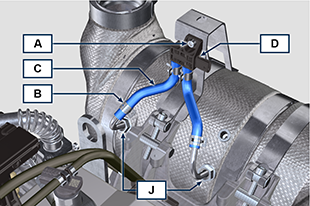

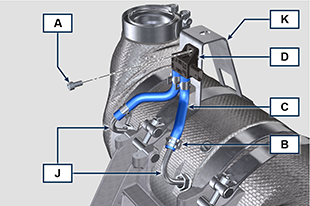

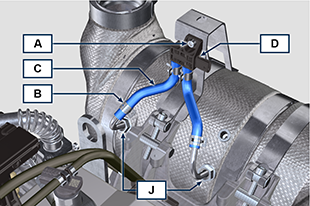

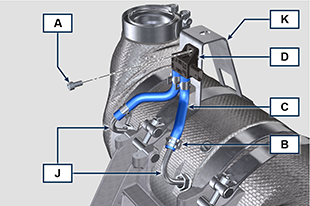

- Unscrew screw A and loosen clamps B, then remove the Delta-P sensor D.

- Disconnect pipes C from their unions J and remove the Delta-P sensor D.

- Unscrew and remove unions J.

|

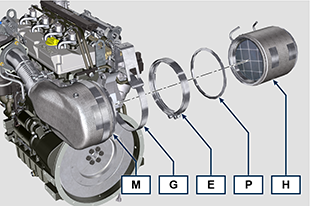

Fig. 11.19

|

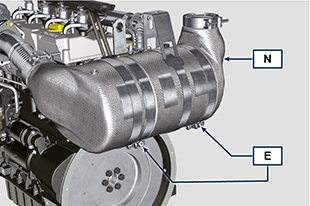

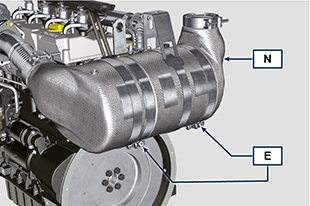

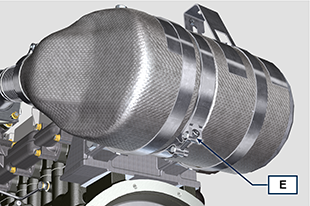

- Loosen clamps E and remove manifold N.

|

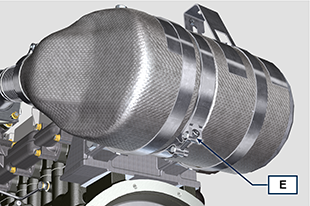

Fig. 11.20

|

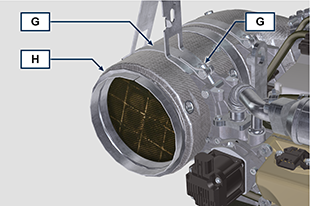

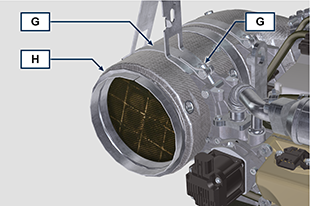

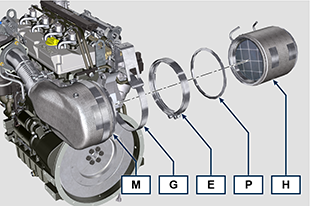

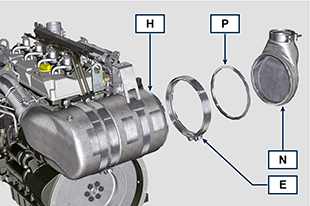

- Loosen clamp G and remove the DPF filter H.

NOTE: do not remove clamp G.

- Inspect the DPF filter to detect any visible signs of oil contamination.

- Put the removed DPF filter in the plastic container supplied with the replacement KIT and send it to your spare parts service using the replacement KIT package.

NOTE: a residual value will be recognised depending on whether the used DPF is intact and recyclable or damaged and requiring a correct disposal.

|

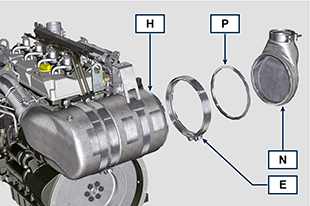

Fig. 11.21

|

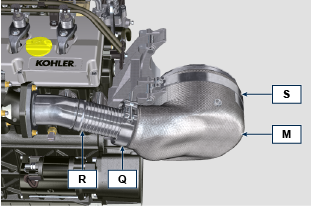

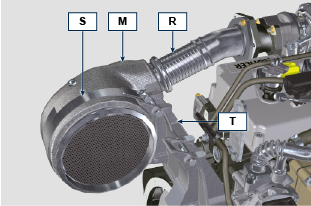

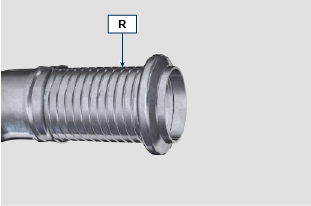

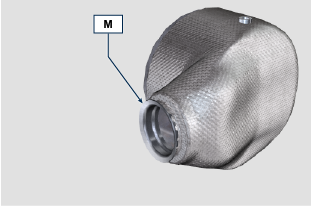

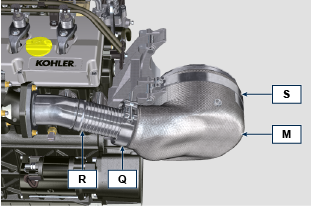

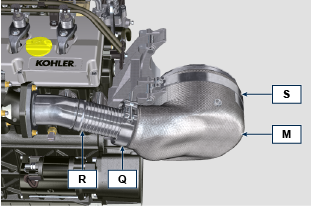

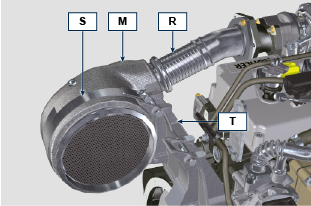

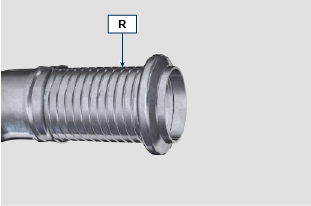

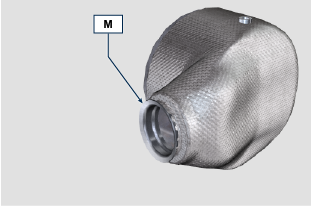

- Loosen the clamps Q and S and remove the manifold with DOC M from the flexible hose R.

|

Fig. 11.22

|

- Fit the new manifold with the DOC filter M on the support T, inserting the flexible hose R inside the inlet of the manifold M.

|

Fig. 11.23

|

Important Important

- Do not apply any tension during the assembly of components.

- Before fastening the manifold M, it must be oriented in the same position as the previously installed DOC filter.

- Tighten the clamp Q (tightening torque of 10 Nm).

- Tighten the clamp S (tightening torque of 12 Nm).

|

Fig. 11.24

|

- Insert the gasket P on the manifold with DOC filter M.

- Insert the new DPF filter H inside clamp G.

- Insert the DPF filter H on manifold M until reaching the gasket P.

|

Fig. 11.25

|

Important Important

- Before fastening the DPF filter H, it must be oriented in the same position as the previous filter.

- Do not apply any tension during the assembly of components.

- Fasten the DPF filter H with clamp E (tightening torque 12 Nm).

|

Fig. 11.26

|

- Insert gasket P on the DPF filter H.

- Insert manifold N on the DPF filter H until reaching the gasket P.

Important Important

- Before fastening manifold N, it must be oriented in the original position.

- Fasten manifold N with clamp E (tightening torque 12 Nm).

|

Fig. 11.27

|

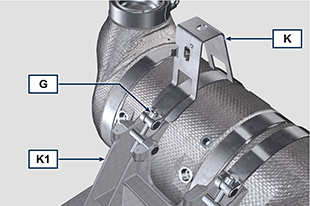

- Position support K in contact with support K1 and fasten clamp G (tightening torque 12 Nm).

|

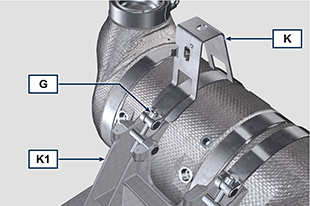

Fig. 11.28

|

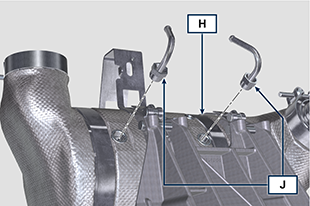

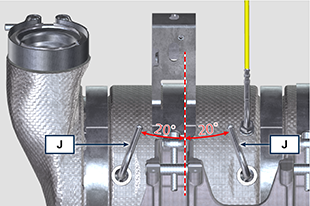

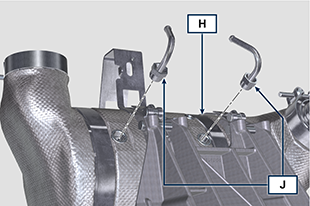

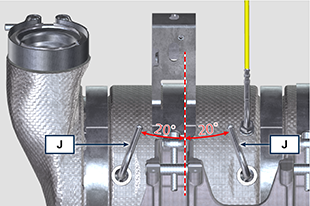

- Screw unions J on the DPF filter H and position them about 20° away from the centre line (as in Fig. 11.30).

|

Fig. 11.29

|

- Fix unions J (tightening torque see service letter 710015).

|

Fig. 11.30

|

- Fit pipes C on unions J and fasten them with clamps B.

- Fix the Delta-P sensor D on its support K by means of screw A (tightening torque 10 Nm).

- Provide the machine owner with the warranty certificate of the new DPF filter KIT installed.

- Perform the "DPF replacement" procedure to reset the ASH & SOOT through the relevant KOHLER diagnostic tool interfaced with the ECU.

|

Fig. 11.31

|

Important

Important Important

Important Important

Important Important

Important

Loading

Loading