|

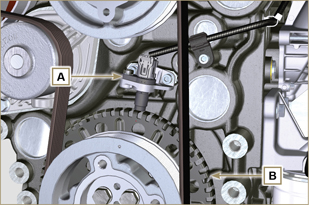

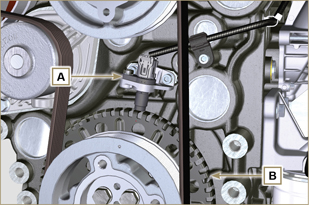

2.14.1 Revolution sensor on target wheel

Speed sensor A is situated on the crankcase.

The sensor detects the signal from the target wheel B (60 - 2teeth) situated on the crankshaft pulley. It sends it to the ECU as an analogical signal.

The sensor sends and analogue signal to the ECU.

The sensor produces a 5V square wave signal having a Hall effect while the crankshaft in rotation detects its position and speed.

The data sent by this sensor enables the ECU to pilot fuel anticipation injection for each piston.

For gap adjusting see Par. 9.13.1.5.

|

Fig 2.35 |

|

2.14.2 Camshaft sensor

Camshaft sensor C is situated on the timing system carter.

The purpose of the camshaft sensor C is to identify the position of the Camshaft control gear D with respect to the engine shaft and consequently the position of the pistons with respect to the T.D.C.

The sensor produces a 5V square wave signal having a Hall effect while the camshaft in rotation detects the phases of the 4 strokes of the 1st cylinder. As a consequence, ECU by means of internal calculations, also recognises the phases of the other cylinders.

The data sent by this sensor enables the ECU to pilot fuel anticipation injection for each piston.

|

Fig 2.36 |

|

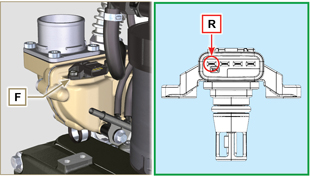

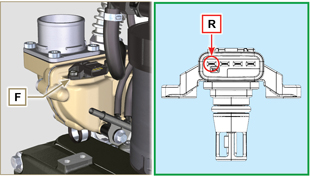

2.14.3 T-MAP sensor

The T-MAP F sensor is situated on the intake manifold.

It detects the input pressure in the intake manifold by means of electrical voltage variation and the air temperature by means of an electrical resistor.

The sensor sends signals to the ECU, which determines the values and modifies the injection strokes.

Tab. 2.35 reports the electrical resistor values according to the intake air temperature.

NOTE: R indicates the pin where it is possible to measure electrical resistance.

Tab 2.35

| °C (°F) |

R (Ω) |

| -30 (-22) |

23475 - 25945 |

| 0 (32) |

5370 - 5935 |

| 25 (77) |

1900 - 2100 |

| 50 (122) |

772 - 854 |

| 100 (212) |

177 - 195 |

| 120 (248) |

107 - 119 |

|

Fig 2.37 |

|

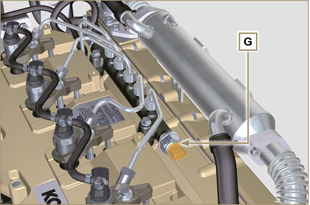

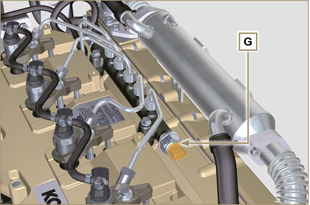

2.14.4 Common Rail pressure sensor

Fuel pressure sensor G assembled on the Common Rail, detects the fuel pressure inside it by means of electrical voltage variation.

Depending on the signal sent, ECU manages the fuel intake valve on the injection pump and, if necessary, modifies the injection strokes.

Important Important |

Fig 2.38 |

|

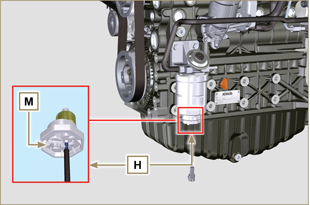

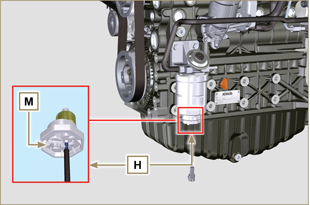

2.14.5 Fuel filter water detection sensor

The water presence sensor H is situated in the fuel filter, which is there to indicate the presence of water in the fuel.

Water, if present in the fuel, because of its greater specific weight separates and settles in the lower part of the filter where there is a specific sensor that, by means of the ECU activates an alarm signal on the dashboard.

The butterfly valve nut M situated in the lower part of the body sensor enables the elimination of any water present in the fuel and prevent malfunctions on components of the injection circuit.

|

Fig 2.39 |

|

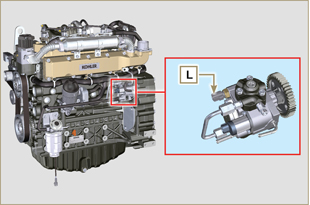

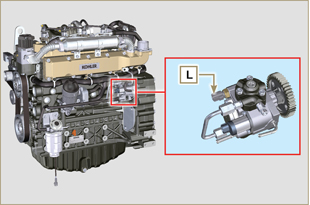

2.14.6 Fuel temperature sensor on the fuel injection pump

The fuel temperature sensor L is situated on the high-pressure fuel injection pump.

The fuel temperature sensor L, measures the temperature of the fuel entering the pump at high pressure.

The signal sent to the ECU is analogue.

The resistance detected by the ECU is proportional to the fuel temperature.

Important ImportantTab. 2.36 reports the electrical resistor values according to the fuel’s temperature.

Tab.2.36

| ºC (ºF) |

R (KΩ) |

| 120 (248) |

2,811 |

| 110 (230) |

2,842 |

| 100 (212) |

2,884 |

| 90 (194) |

2,940 |

| 80 (176) |

3,018 |

| 70 (158) |

3,128 |

| 60 (140) |

3,284 |

| 50 (122) |

3,511 |

| 40 (104) |

3,850 |

| 30 (84) |

4,360 |

| 20 (66) |

5,150 |

| 10 (50) |

6,400 |

| 0 (32) |

8,440 |

| -10 (14) |

11,860 |

| -20 (-4) |

17,700 |

| -30 (-22) |

28,102 |

|

Fig 2.40 |

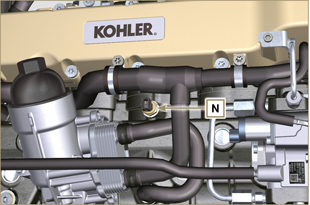

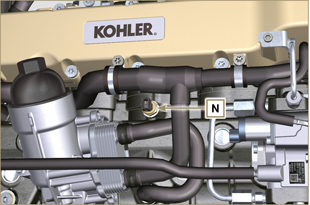

2.14.7 Oil pressure switch

Oil pressure switch N is assembled on the crankcase near to the injection pump.

It is a N/C sensor, calibrated at 0.6 bar ± 0.1 bar.

With oil low pressure the sensor closes the electrical circuit and the warning lamp in the panel board switches on. |

Fig 2.41 Fig 2.41 |

|

2.14.8 Coolant temperature sensor

The P coolant temperature sensor of the coolant circuit is applied to the cylinder head on the side of the thermostatic valve.

It is used by the ECU in order to obtain information regarding the coolant temperature (from PIN R).

NOTE: R refers to the pin where it is possible to measure the electrical resistor.

Tab 2.37

| CHARACTERISTICS |

| Temperature °C |

R min Ω |

R max Ω |

| -35 |

53983 |

73806 |

| -30 |

39229 |

52941 |

| -15 |

18006 |

20825 |

| 0 |

7095 |

8929 |

| +30 |

1717 |

2039 |

| +60 |

520 |

589 |

| +90 |

188 |

204 |

| +120 |

76 |

84 |

|

Fig 2.42 Fig 2.42

NOTE: R indicates the pin where it is possible to measure electrical resistance.

|

|

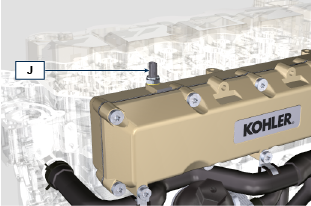

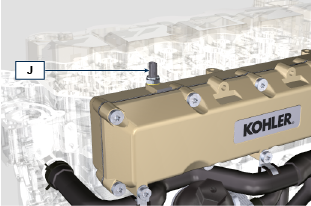

2.14.9 EGR-T sensor (versions with DPF filter only)

The EGR-T J sensor is placed on the air intake manifold after the EGR gas inlet and measures the temperature of the air mixed with EGR gas coming from the turbocharger. Tab. 2.43b shows the electric resistance values based on the intake air temperature.

Tab 2.43b

| °C (°F) |

R (kΩ) |

| -40 (-40) |

130.3 |

| 0 (32) |

33.87 |

| 25 (77) |

17.17 |

| 50 (122) |

9.603 |

| 100 (212) |

3.739 |

| 150 (302) |

1.796 |

| 200 (392) |

1.000 |

|

Fig 2.48a

|

|

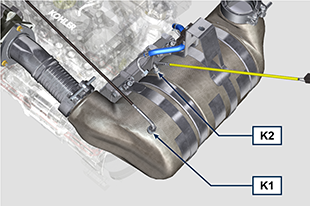

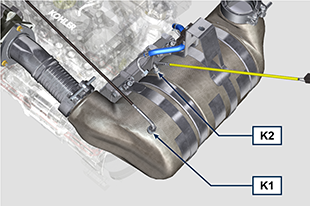

2.14.10 EGTS sensor (yellow - black)

The EGTS sensors K1 and K2 are placed on the ATS system, K1 with black wire before the DOC, K2 with yellow wire after the DOC.

They are both needed for the DPF filter regeneration strategies.

Tab. 2.37b shows the electric resistance values based on the intake air temperature.

Tab 2.43c

| °C (°F) |

R (kΩ) |

| -40 (-40) |

133,8 |

| 0 (32) |

34,49 |

| 50 (122) |

9,749 |

| 100 (212) |

3,771 |

| 150 (302) |

1,803 |

| 200 (392) |

1,002 |

| 250 (482) |

0,6173 |

| 300 (572) |

0,4127 |

| 350 (662) |

0,2934 |

| 400 (752) |

0,2186 |

| 450 (842) |

0,1690 |

| 500 (932) |

0,1345 |

| 550 (1022) |

0,1097 |

| 600 (1112) |

0,0912 |

| 650 (1202) |

0,0771 |

| 700 (1292) |

0,0661 |

| 750 (1382) |

0,0574 |

| 800 (1472) |

0,0503 |

| 850 (1562) |

0,0445 |

|

Fig 2.48b

|

|

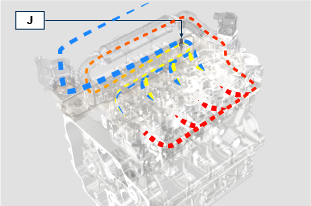

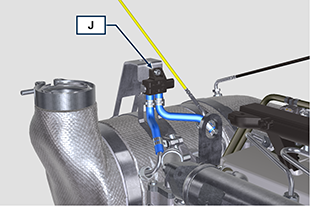

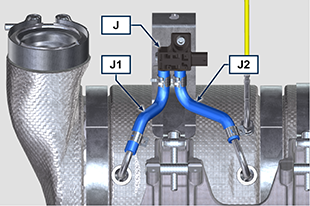

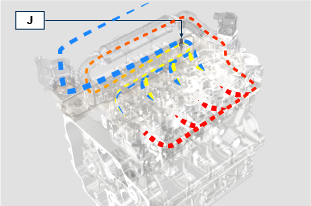

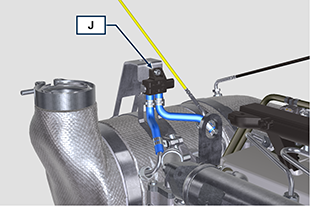

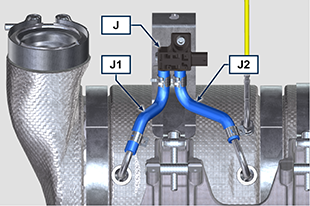

2.14.11 Sensore Delta-P

Delta-P sensor

The Delta-P sensor J detects the clogging level of the DPF filter.

Operating temperature: -30°C - +120°C.

Important Important

- Connect the J1 and J2 pipes to the Delta-P sensor exclusively as shown in Fig. 2.48c.

|

Fig 2.48c

Fig 2.48c

|

|

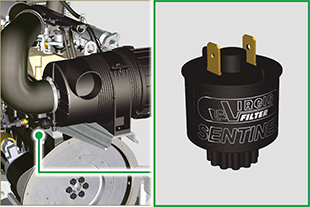

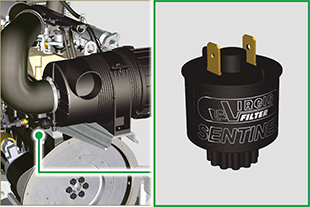

2.14.12 Air cleaner clogging switch

NOTE: Component not necessarily supplied by KOHLER.

The switch is assembled on the air cleaner. When the filter is clogged, it sends a signal to the panel.

Features:

- Operating temperature: -30 °C / +100°C

- Contact usually open.

- Contact closed by vacuum: -50 mbar.

|

Fig. 2.48d |

Important

Important

Important

Important

Fig 2.41

Fig 2.41 Important

Important

Fig 2.42

Fig 2.42

Loading

Loading