|

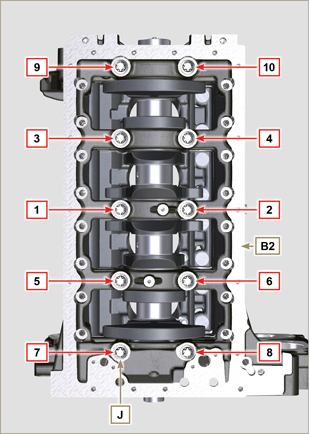

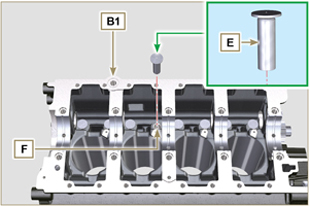

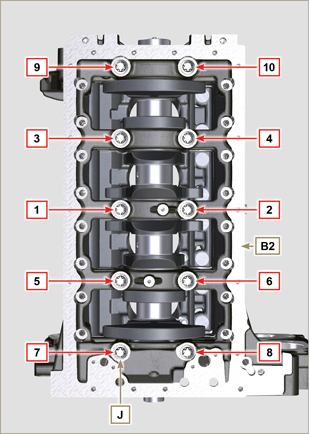

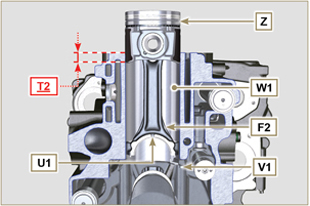

Fig 9.9

|

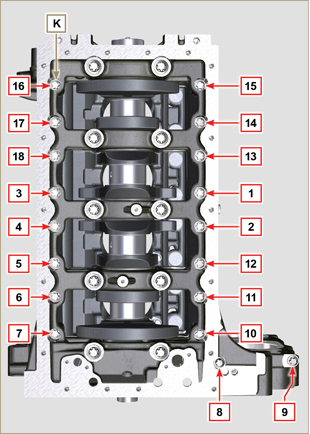

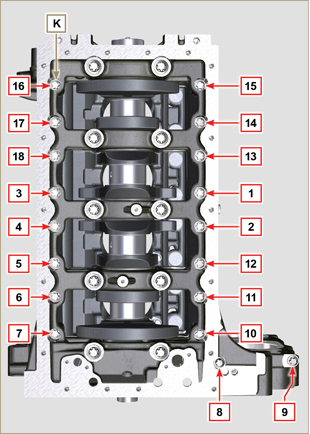

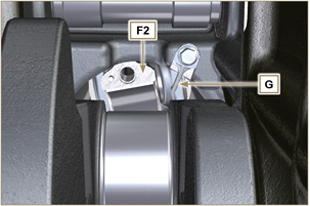

Fig 9.10

|

|

Tab 9.2

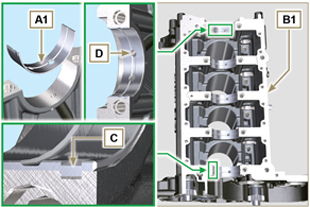

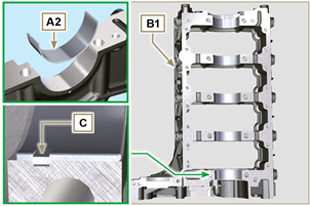

| CYCLE |

SCREWS |

TORQUE |

| 1 |

J - Torx M14x1,5 |

60 Nm |

| 2 |

K - Torx M10x1.25 |

30 Nm |

| 3 |

J - Torx M14x1,5 |

45° |

| 4 |

J - Torx M14x1,5 |

45° |

Important Important

- The fastening bolts J, K must be replaced every time they are assembled.

- Failure to adhere to the bolt fixing procedures may compromise the functionality of the engine, and also may cause damage to persons and property.

- Tighten capscrews J, K observing the cycles, tightening, and subsequent rotation as indicated in Tab. 9.2.

- Apply "Molyslip AS COMPOUND 40" on the threads and under the head of capscrews J and K and manually tighten them until their stop.

- Tightening the screws J, K strictly following the sequence indicated in the Fig. 9.9 or Fig. 9.10 and the tightening torque indicated in the Tab. 9.2.

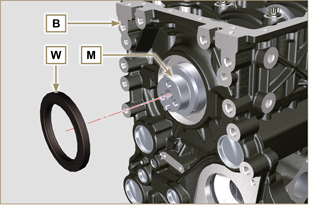

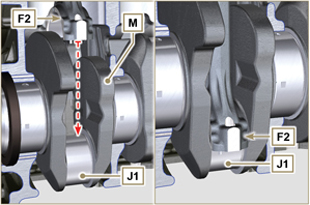

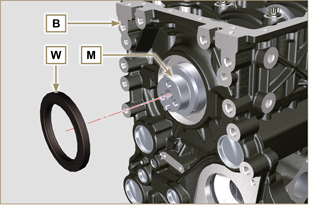

- Check that crankshaft M rotates smoothly.

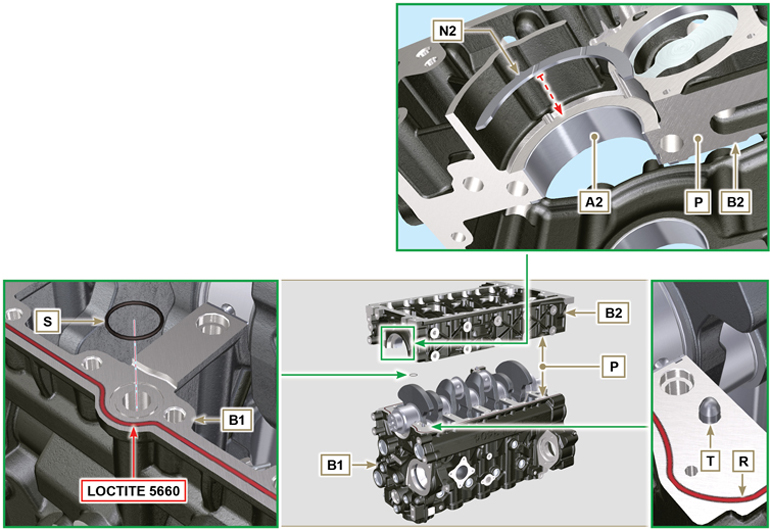

- Insert gasket W into the seat of crankcase B (ST_47).

|

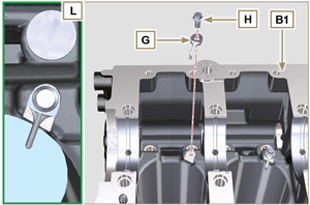

Fig 9.11

|

|

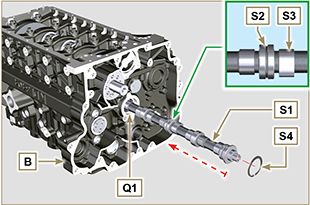

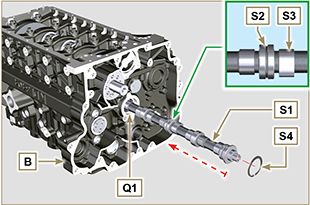

9.3.6 Camshaft

- Lubricate the pins S2 the cams S3 of the camshaft S1 all the housing Q1 with oil.

- Insert the camshaft S1 all the way into its housing Q1.

- Fit the lock ring S4 on to the crankcase B to hold the position of the camshaft S1.

|

Fig 9.12

|

|

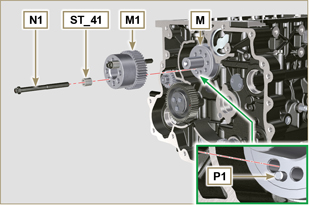

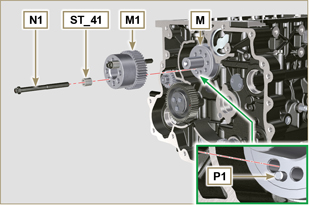

9.3.7 Timing system gear

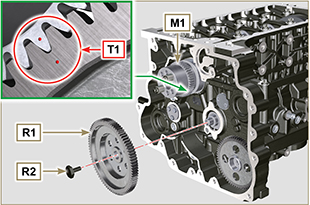

- Check that the pin P1 is correctly fitted on the crankshaft M.

- Position the gear M1 on the crankshaft M respecting the reference with pin P1.

- Fully tighten the screw N1 interposing tool ST_41 between N1 and M1.

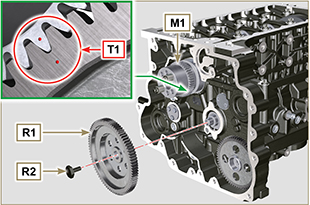

- Position the gear R1 on the camshaft S1 observing the marks T1 of the gear M1.

Important Important

- Failure to comply with the marks T1 on the gears M1 and R1 causes engine malfunction and serious damage.

- Fastening capscrew R2 must be replaced every time it is assembled.

- Assemble gear R1 by means of capscrew R2 (tightening torque 100 Nm).

- Check that crankshaft M rotates smoothly.

|

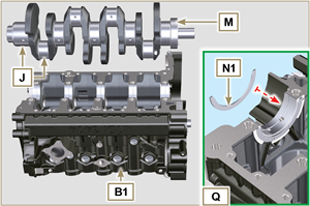

Fig 9.13

Fig 9.14

|

|

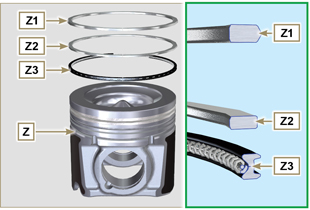

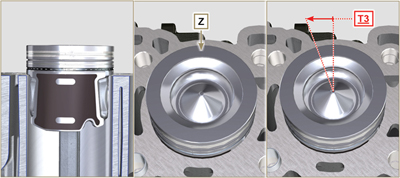

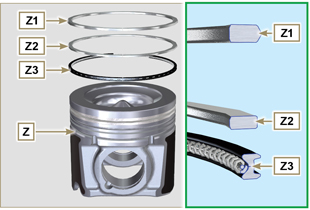

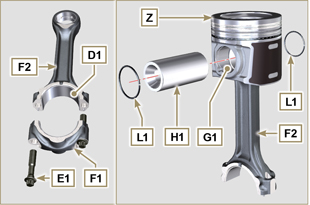

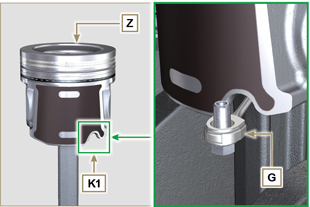

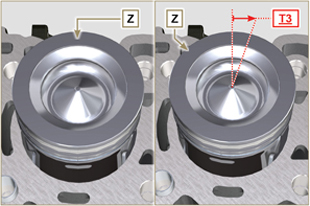

9.3.8 Piston rings

- Perform the operations described in Par. 8.5.3.

- Put the scraper ring Z3 onto the piston Z.

- Put the 2° seal ring Z2 on the piston Z.

- Put the 1° seal ring Z1 onto the piston Z.

- Perform the operations described in Par. 8.5.4.

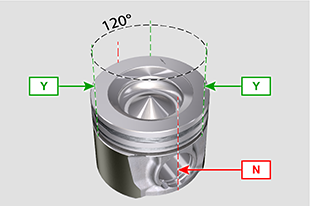

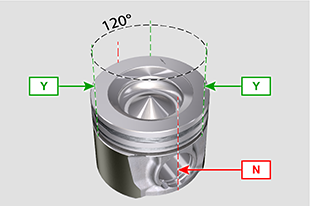

- Position the segment openings with a 120° angle between them (Y).

NOTE: do not use the segment opening with the pin hole (N)

- Lubricate the piston skirt and piston rings with oil.

|

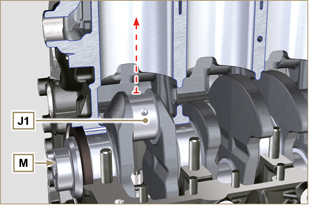

Fig 9.15

Fig 9.16

|

|

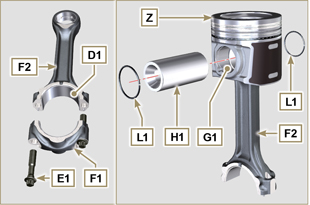

9.3.9 Piston

Importante Importante

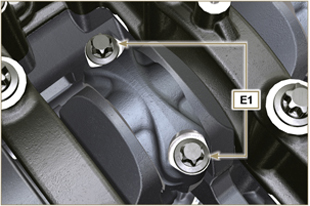

- The fastening bolts E1 must be replaced every time they are assembled.

- Before proceeding to the assembly of the piston and connecting rod, carry out the checks described in Par. 8.5.1.

- Always replace the bearings D1 after each assembly.

- Mate components respecting references at Par. 7.12.5.

- Loosen the screws E1 and remove the connecting rod cap F1.

- Insert the connecting rod F2 into the piston Z and align the seats G1.

- Insert the gudgeon pin H1 into the seat G1 for the assembly of the connecting rod and piston unit.

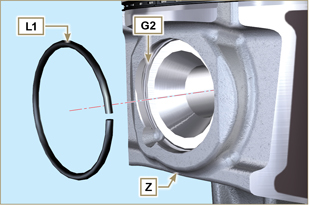

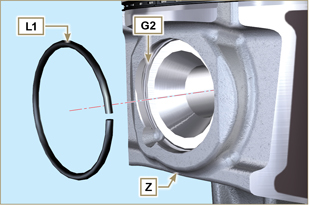

- Insert the lock rings L1 inside the seat G2 of the piston Z to lock the gudgeon pin H1.

|

Fig 9.17

Fig 9.18

|

Important

Important Importante

Importante

Important

Important

Important

Important Important

Important Importante

Importante Important

Important

Important

Important Important

Important

Important

Important Important

Important

Loading

Loading