=

Search

1

General Information

This manual contains the instructions needed to carry out proper use and maintenance of the engine, therefore it must always be available, for future reference when required. This manual is an integral part of the engine, in the event of transfer or sale, it must be attached to it. Safety pictograms can be found on the engine and it is the operator's responsibility to keep them in a perfectly visible place and replace them when they are no longer legible. Information, description and pictures in this manual reflect the state of the art at the time of the marketing of engine. However, development on the engines is continuous. Therefore, the information within this manual is subject to change without notice and without obligation. Lombardini Marine reserves the right to make, at any time, changes in the engines for technical or commercial reasons. These changes do not require Lombardini Marine to intervene on the marketed production up to that time and not to consider this manual as inappropriate. Any additional section that Lombardini Marine will deem necessary to supply some time after the main text shall be kept together with the manual and considered as an integral part of it. The information contained within this manual is the sole property of Lombardini Marine. As such, no reproduction or replication in whole or part is allowed without the express written permission of Lombardini Marine.

The paragraphs, tables and figure are divided into chapter with their progressive numbers. Ex: Par. 2.3 - chapter 2 paragraph 3.Tab. 3.4 - chapter 3 table 4.Fig. 5.5 - chapter 5 figure 5.The references of the objects described in the text and in figure and number are indicated by letters, which are always and only related to the paragraph you are reading unless there are specific references to other figures or paragraphs. NOTE: All data, measurements and relevant symbols are shown in the glossary section.

Conforme alla normativa 9768 Stage III A per i mercati CE.

Authorized service centers can be found on our web site: http://www.lombardinimarine.com. If you have any questions regarding your warranty rights and responsibilities or the location of the nearest authorised service location, contact +39 07462251 or go to http://www.lombardinimarine.com.

The engine identification nameplate is located on side A or B as below. Fig. 1.3 (*1): the engine model reported on the name plate in Fig. 1.3 is generic. For a specific model, refer to the engine model shown on the name place situated on the rocker arm cover, as shown in Fig. 1.4. Fig. 1.4

2

Technical information

- 4-stroke, in-line cylinders Diesel engine;-Liquid-cooling system;- 4 valves per cylinder with hydraulic tappets;- Direct Injection.

Tab. 2.1 TECHNICAL DATA UNIT OF MEASURE Engine type KDI 1903 M-MP Cylinders n. 3 Bore mm 88 Stroke mm 102 Displacement cm3 1861 MAX INCLINATION DURING OPERATION (even in combined) α 35° MAX (transversal) α 15° MAX (longitudinal) OIL CAPACITY (MAX level.) including oil filter standard version L 8.9 DRY WEIGHT Kg 277

Fig. 2.1

2.4.1 Engine oil Important The engine may be damaged if operated with improper oil level. Do not exceed the MAX level because a sudden increase in engine rpm could be caused by its combustion. Use only the recommended oil to ensure adequate protection, efficiency and service life of the engine. The use of lubricants other than recommended may shorten the engine life. Viscosity must be appropriate to the ambient temperature to which the engine is to be exposed (Par. 2.4.1.1). Danger Prolonged skin contact with the exhausted engine oil can cause cancer of the skin. If contact with oil cannot be avoided, thoroughly wash your hands with soap and water as soon as possible. For the exhausted oil disposal, refer to the Par. 6.9. 2.4.1 SAE oil classification In the SAE classification, oils are identified according to viscosity without considering any other qualitative characteristic. The code is composed of two numbers, which indicate, and must correspond to, the ambient temperature in which the engine operates, the first number refers to the viscosity when cold, for use during winter ("W"), while the second number is for viscosity at high temperatures. Use oil viscosity based on the experienced air temperature range during the period between oil changes as indicated in the table below. Kohler / Rehlko X-treme 10W-40 formula pro; X-treme 10W-40; X-treme 5W-40 oil are preferred: Oils meeting the following specifications are also recommended. Tab. 2.2 RECCOMENDED OIL VISCOSITY SAE 15w-40 (+15°c ÷ +45°c) 10w-30 (-15°c ÷ +30°c) 5w-30 (-30°c ÷ +30°c) 5w-40 (-30°c ÷ +45°c) WITH SPECIFICATIONS API CH4 CJ4 CH4 CH4/ CJ4 ACEA E4 - E5 - E7 CLASSIFICATION DESCRIPTION AREA SPECIFICATION E4 High performance (Euro 1 - 2 - 3 Engines) heavy duty E5 High performance (Euro 1 - 2 Engines) heavy duty E7 High power over long distances (Euro 4 - 5 engines) 2.4.2 Reversing gear oilNOTE: Refer to the technical documentation of the reversing gear supplied with the engine.

Important Use of other types of fuel could damage the engine. Do not use dirty diesel fuel or mixtures of diesel fuel and water since this will cause serious engine faults. Any failures resulting from the use of fuels other than recommended will not be warranted. Warning Clean fuel prevents the fuel injectors from clogging. Immediately clean up any spillage during refuelling. Never store diesel fuel in galvanized containers (i.e. coated with zinc). Diesel fuel and the galvanized coating react chemically to each other, producing flaking that quickly clogs filters or causes fuel pump and/or injector failure. 2.3 FUEL COMPATIBILITY EN 590 (biodiesel content max. 7% (V/V)) ASTM D 975 Grade 1-D S15 ASTM D 975 Grade 2-D S15 NATO F-54, equivalent to diesel fuel in accordance with EN 590 EN 590 or ASTM D 975 Grade 1, 2 -D S15 Arctic Diesel JIS K 2204 No. 1, No. 2 NOTE: In a warranty case the customer must prove by a certificate from the fuel supplier that an allowed fuel was used. KDI Mechanical Injection Tier 3 – Stage IIIA certified Engines (w and w/o EGR) Those engines are designed for fuels in accordance with EN 590 and ASTM D975 for a cetane number of at least 45. Since those engines are not equipped with exhaust gas after-treatment, they can be operated with diesel fuels with sulfur content up to 500 mg/kg (ppm). Compliance with the emission requirements is guaranteed only with sulfur content up to 15 mg/kg (ppm).Engines operated with fuels as per EN 590 and ASTM D975 with sulfur content < 15mg/kg have an oil changing interval of 500hrs. Fuels with a sulfur content > 500 mg/kg demand a shorter lubricating oil change interval. This is set at 250hrs. However, the engine oil must be changed when the Total Base Number TBN is reduced to 6.0 mgKOH/g test method ASTM D4739. With high fuel sulfur content fuel this may happen at 125hrs. Do not use low SAPS oils. KDI Mechanical Injection Uncertified Engines (no EGR Engines) Those engines are designed for fuels in accordance with EN 590 and ASTM D975 for a cetane number of at least 45. Since those engines are not equipped with exhaust gas after-treatment, they can be operated with diesel fuels with sulfur content up to 2000 mg/kg (ppm).Engines operated with fuels as per EN 590 and ASTM D975 with sulfur content < 15mg/kg have an oil changing interval of 500hrs. Fuels with a sulfur content > 500 mg/kg demand a shorter lubricating oil change interval. This is set at 250hrs. However, the engine oil must be changed when the Total Base Number TBN is reduced to 6.0 mgKOH/g test method ASTM D4739 2.5.1 Fuel for low temperatures When operating the engine in ambient temperatures lower than 0 degrees C, use suitable low temperature fuel normally available from fuel distributors and corresponding to the specifications of Tab. 2.3. These fuels reduce the formation of paraffin in diesel at low temperatures. When paraffin forms in the diesel, the fuel filter becomes blocked interrupting the flow of fuel. 2.5.2 Biodiesel fuel Fuels containing 10% methyl ester or B10, are suitable for use in this engine provided that they meet the specifications listed in the Tab. 2.3. DO NOT USE vegetable oil as a biofuel for this engine. 2.4 BIODIESEL COMPATIBILITY Biodiesel according to EN 14214 (only permissible for mixture with diesel fuel at max. 10% (V/V)) US biodiesel according to ASTM D6751 – 09a (B100) (only permissible for mixtures with diesel fuel at 10% (V/V)) 2.5.3 Synthetic fuels: GTL, CTL, BTL, HVIt is a well-known fact that engines which are operated for longer periods with conventional diesel fuel and then converted to synthetic fuels suffer shrinkage of polymer seals in the injection system and thus fuel leaks. The reason for this behavior is that the aromatic-free synthetic fuels can lead to a change in the selling behavior of polymer seals.Therefore, conversion from diesel fuel to synthetic fuel may only be done after changing the critical seals. The problem of shrinkage does not occur when an engine was operated with synthetic fuel from the start. 2.5.4 Non-Road Fuels Other non-road fuels may be used if they comply with all the limit values of EN 590 except for the fuel density, the cetane number and the sulfur content. The following limits apply for these parameters: 2.5 FUEL PARAMETER UNIT LIMIT VALUE Cetane number Min. 49 Fuel density at 15°C Kg/m3 820 - 860 Sulfur content mg/kg or ppm max. 500 2.5.5 Jet FuelsOnly for KDI Mechanical Injection Uncertified Engines (no EGR Engines).The following jet fuels can be used but only adopting an additional fuel filter with lubricity doser: 2.6 FUEL F-34/F-35 (kerosene, NATO designation) JP-8 (kerosene, US military designation) F-44 (kerosene, NATO designation JP-5 (kerosene, US military designation) F-63 (kerosene, NATO designation, equivalent to F-34/F-35 with additives) Jet A (kerosene for civil aviation) F-65 (kerosene, NATO designation, 1:1 mixture of F-54 and F-34/F-35) Jet A1 (kerosene for civil aviation) 2.5.6 Emission-Related Installation InstructionsFailing to follow the instructions in the applications guidebook when installing a certified engine in a piece of nonroad equipment violates federal law (40 CFR 1068.105(b)), subject to fines or other penalties as described in the Clean Air Act.OEM must apply a separate label with the following statement: “ULTRA LOW SULFUR FUEL ONLY” near the fuel inlet.Ensure you are installing an engine appropriately certified for your application. Constant speed engines may only be installed on constant speed equipment for constant speed operation.If you install the engine in a way that makes the engine's emission control information label hard to read during normal engine maintenance, you must place a duplicate label on the equipment, as described in 40 CFR 1068.105.

Kohler / Rehlko XtendedTM prediluted coolant 50% ethylene glycol OAT is preferred. Coolant meeting the following specifications are also recommended. A mixture of 50% demineralized water and 50% low silicate ethylene glycol based coolant liquid must be used.Use a Long Life or Extended Life Heavy Duty OAT coolant free of: silicates, phosphates, borates, nitrites and amines. The following ethylene-glycol based engine coolant for all models within KDI engine family may be used: OAT (Organic Acid Technology) Low Silicate: ASTM D-3306 D-6210 HOAT (Hybrid Organic Acid Technology) Low Silicate: ASTM D-3306 D-6210 The above coolants in concentrated formulation must be mixed with distilled, deionized, or demineralized water. A pre-mixed formulation (40-60% or 50-50%) can be used directly when available. Important Do not mix ethylene glycol and propylene glycol based coolants. Do not mix OAT and HOAT based coolant. OAT performance life can be drastically reduced if contaminated with nitrite-containing coolants. Never use automotive-type coolants. These coolants do not contain the correct additives to protect heavy – duty diesel engines. OAT coolants are maintenance free up to 6 years or 6000hrs of operation , provided that the cooling system is topped up using the same type of coolant. Do not mix different coolant types. Test the coolant condition annually with coolant test strips.HOAT are not all maintenance free and it is recommended to have SCA (Supplemental Coolant Additives) added at the first maintenance interval.

Battery not supplied by Kohler Tab. 2.5 RECOMMENDED BATTERIES AMBIENT TEMPERATURE BATTERY TYPE > - 15°C 12V 100 Ah - 800 CCA/SAE -15°C ÷ -25°C 12V 110 Ah - 950 CCA/SAE < - 25°C 12V 120 Ah - 1000 CCA/SAE

Tab. 2.6 shows the control panel components. Tab 2.6 POS. DESCRIPTION A Panel ignition switch with key switch B Engine on/off push button C Engine rpm indicator D Engine data or errors display E Engine data or errors push button F Maintenance errors reset push button Fig 2.2 Tab. 2.7 shows data that can be consulted on display D by pressing push button E. Tab 2.7 POS. DESCRIPTION Coolant temperature (°C) Oil pressure (bar) Battery voltage (V) Total and partial hours of operation (h) To reset partial hours, simultaneously press push buttons E and F for 3 seconds. Hours left for maintenance (h) Backlighting adjustment Press push button E for 3 seconds Press push button E to decrease brightness or F to increase it

3

Safety information

The intended use of the engine is in conformity with the machine on which it is mounted. Any use of the machine other than that described cannot be considered as complying with its intended purpose as specified by Lombardini Marine. Lombardini Marine declines all responsibility for any change to the engine not described in this manual made by unauthorized Lombardini Marine personnel. A proper use of the engine, a strict observance of the rules listed below and the rigorous application of all these precautions will avoid the risk of accidents or injuries. Those who carry out the use and maintenance on the engine must wear the safety equipment and the accident-prevention guards. Lombardini Marine declines all direct and indirect liability for failure to comply with the standards of conduct contained in this manual. Lombardini Marine cannot consider every reasonably unforeseeable misuse that may cause a potential danger.

3.2.1 Note for OEM/installer When installing the KDI engines, always bear in mind that any variation to the functional systems may result serious failures to the engine. Install the engine by strictly following the installation manual. Any changes in the installation procedure or engine must be approved by Lombardini Marine. Failure to do so shall not hold it responsible for operation malfunctions and any damage to the engine. 3.2.2 Note for end user The following indications are dedicated to the user of the machine in order to reduce or eliminate risks concerning engine operation and the relative routine maintenance work. The user must read these instructions carefully. Failure to do this could lead to serious danger for his personal safety and health and that of any persons who may be in the vicinity of the machine. Make sure transmission is in neutral on ignition. The engine must not operate in places containing inflammable materials, in explosive atmospheres, where there is dust that can easily catch fire unless specific, adequate and clearly indicated precautions have been taken and have been certified for the machine. Children and animals must be kept at a due distance from operating machines in order to prevent hazards deriving from their operation. Thoroughly wash and clean all the external parts of the engine before performing any operation, in order to avoid the accidental introduction of impurities/foreign bodies. Use only water and/or appropriate products to clean the engine. If cleaning engine with a pressure washer or steam cleaner, it is important to maintain a minimum distance of at least 200mm between the surface to be washed and the nozzle. Avoid directing the nozzle on electrical components, cable connections and sealed rings (oil seals etc). Thoroughly wash and clean the area surrounding the engine following the instructions provided by machine manufacturer. Fuel and oil are inflammable. The tank must only be filled when the engine is off. Before starting, dry any spilt fuel. Fuel vapour is highly toxic. Only refuel outdoors or in a well ventilated place. Do not smoke or use naked flames when refuelling. During operation, the surface of the engine can become dangerously hot. Avoid touching the exhaust system in particular. Before proceeding with any operation on the engine, stop it and allow it to cool. Always open the radiator plug or expansion chamber with the utmost caution, wearing protective garments and goggles. The coolant fluid is under pressure. Never carry out any inspections until the engine has cooled. The oil must be drained whilst the engine is hot. Particular care is required to prevent burns. Do not allow oil to come into contact with the skin because of the health hazards involved. It is recommended to use an oil intake pump. During operations that involve access to moving parts of the engine and/or removal of rotating guards, disconnect and insulate the negative wire (-) of the battery to prevent accidental short-circuits and to stop the starter motor from being energized. Check belt tension only when the engine is off. Fully tighten the tank cap each time after refuelling. Do not fill the tank right to the top but leave an adequate space for the fuel to expand. To start the engine follow the specific instructions provided in the engine and/or machine operating manual. Do not use auxiliary starting devices not originally installed on the machine (e.g. Startpilot). Before starting, remove any tools that were used to service the engine and/or machine. Make sure that all guards have been refitted. Do not mix fuel with elements such as oil or kerosene. Failure to comply with this prohibition will cause the non-operation of the catalyst and non-observance of the emissions declared by Lombardini Marine. Pay attention to the temperature of the oil filter when the filter itself is replaced. Only check, top up and change the coolant fluid when the engine is off and reached the ambient temperature. Coolant fluid is polluting, it must therefore be disposed of in the correct way. Do not use air and water jets at high pressures on cables, connectors and injectors. Important Only use the eyebolts A installed by Lombardini Marine to move the engine (Fig. 3.1). The angle between each lifting chain and the eyebolts shall not exceed 15° inwards. The correct tightening of the lifting screws is 25 Nm. Do not interpose spacers or washers between the eyebolts and engine head. Fig. 3.1

To ensure safe operation please read the following statements and understand their meaning. Also refer to your equipment manufacturer's manual for other important safety information. This manual contains safety precautions which are explained below. Please read them carefully. Adhesive safety plates The following is a list of the adhesive safety plates that may be found on the engine, which indicate potential points of danger to the operator. Read the Operation and Maintenance handbook before performing any operation on the engine. Hot Parts.Danger of burns. Presence of rotating parts.Danger of jamming or cutting. Presence of explosive fuel.Danger of fire or explosion. Presence of steam and pressurized coolant.Danger of burns. WarningsHereunder is a list of safety warnings that may be found in the manual, which advise you to pay attention when carrying out particular procedures that may be potentially dangerous to the operator or things. DangerThis indicates situations of grave danger which, if ignored, may seriously threaten the health and safety of individuals. ImportantThis indicates particularly important technical information that should not be ignored. WarningThis indicates that failure to comply with it can cause minor damage or injury. Safety guardsHereunder is a list of safety guards that must be worn prior to carrying out any type of operation and to avoid potentialharm to the operator. Use suitable protective gloves before carrying out any type of operation. Use protective goggles before carrying out any type of operation. Use earmuffs before carrying out any type of operation.

ACCIDENTAL START Accidental Starts can cause severe injury or death. Before working on the engine or equipment, disconnect the battery negative (-) wire. HOT PARTS Hot Parts can cause severe burns. Engine components can get extremely hot from operation. Do not touch engine while operating or just after stopping. Never operate the engine with heat shields or guards removed. ROTATING PARTS Rotating Parts can cause severe injury. Stay away while engine is in operation. Keep hands, feet, hair, and clothing away from all moving parts to prevent injury. Never operate the engine with covers, shrouds, or guards removed. LETHAL EXHAUST GASES Carbon Monoxide can cause severe nausea, fainting or death. Avoid inhaling exhaust fumes and never run the engine in a closed building or confined area. Carbon monoxide is toxic, odorless, colorless, and can cause death if inhaled. ELECTRICAL SHOCK Electrical Shock can cause injury. Do not touch wires while engine is running. HIGH PRESSURE FLUID RISK OF PUNCTURE High Pressure Fluids can puncture skin and cause severe injury or death. Do not work on fuel system without proper training or safety equipment. Fluid puncture injuries are highly toxic and hazardous. If an injury occurs, seek immediate medical attention. EXPLOSIVE FUEL Explosive fuel can cause fires and severe burns. Fuel is flammable and its vapours can ignite. Store fuel only in approved containers, in well ventilated, unoccupied buildings. Do not fill the fuel tank while the engine is hot or running, since spilled fuel could ignite if it comes in contact with hot parts or sparks from ignition. Do not start the engine near spilled fuel. Never use fuel as a cleaning agent. EXPLOSIVE GAS Explosive Gas can cause fires and severe acid burns. Charge battery only in a well ventilated area. Keep sparks, open flames, and other sources of ignition away from the battery at all times. Batteries produce explosive hydrogen gas while being charged. Keep batteries out of the reach of children. Remove all jewelry when servicing batteries. Before disconnecting the negative (-) ground cable, make sure all switches are OFF. If ON, a spark will occur at the ground cable terminal which could cause an explosion.

Every organisation has a duty to implement procedures to identify, assess and monitor the influence of its own activities (products, services, etc.) on the environment. Procedures for identifying the extent of the impact on the environment must consider the following factors: Liquid waste. Waste management. Soil contamination. Atmospheric emission. Use of raw materials and natural resources. Regulations and directives regarding environmental impact. In order to minimise the impact on the environment, Lombardini Marine now provides a number of indications to be followed by all persons handling the engine, for any reason, during its expected lifetime. - All components and fluids must be disposed of in accordance with the laws of the country in which disposal is taking place. - Keep the fuel and engine control systems and the exhaust pipes in efficient working order to limit environmental and noise pollution. - When discontinuing use of the engine, select all components according to their chemical characteristics and dispose of them separately.

Fig. 3.2

4

Information about use

Read carefully the following pages and carry out the operations described below in accordance with the instructions specified. Important Non compliance with the operations described in the following pages involves the risk of damages to the engine and vehicle on which it is installed as well as personal and/or property damage. Increase the frequency of maintenance operations in heavy working conditions (engine starts but stops, very dusty and hot environments, etc..).

NOTE: For the first 50 hours of engine operation, it is advisable not to exceed 75% of the maximum power supplied.

4.3.1 Starting Check the level of the engine oil, fuel and coolant and fill if necessary (Par. 4.5 e Par. 4.6). Put the ignition key in the ignition switch. Tun the key to 1 position. Press the Start push button for it to start automatically. Important RPM reading delay is normal. If engine does not start after two attempts see Tab. 7.1 and Tab. 7.2 to found the cause. Fig. 4.1 4.3.2 After starting Warning Make sure that all the warning lights on the control panel are off when the engine is running. Check for any leakages from the pipes on first start-up AMBIENT TEMPERATURE TIME ≤-20°C 2 minutes from -20°C a -10°C 1 minutes from -10°C a -5°C 30 seconds from -5°C a 5°C 20 seconds ≥ 5°C 15 seconds 4.3.3 Turning off Do not turn off the engine with a full load or when it is running at the maximum rotation speed. Leave it running at idle speed without a load for approximately 1 minute. Press the Stop push button (the engine turns off) and turn the key to position 0.

Important Before proceeding with operation, read Par. 3.2.2. Danger Fill the engine off. The only approved fuels are those listed in Tab. 2.3. In those countries where fuel has a high sulphur content, its is advisable to lubricate the engine with a high alkaline oil or alternatively to replace the lubricating oil recommended by Lombardini Marine more frequently. To avoid explosions or fire outbreaks, do not smoke or use open flames during the operations. Fuel vapours are highly toxic.Only carry out the operations outdoors or in a well ventilated place. Keep your face well away from the fuel fill to prevent harmful vapours from being inhaled. Dispose of fuel in the correct way and do not litter as it is highly polluting. When refuelling, it is advisable to use a funnel to prevent fuel from spilling out.The fuel should also be filtered to prevent dust or dirt from entering the tank. Do not overfill the fuel tank. Leave room for the fuel to expand.

Important For safety precautions see Par. 2.4. Before proceeding with operation, read Par. 3.2.2. Place engine on horizontal surface to ensure accurate measurement of filling. Loosen the oil filler cap A or the oil filler cap C if the cap A is not accessible. Add the type of oil recommended (Tab. 2.1 and Tab. 2.2). Fig 4.2 Remove the oil dipstick B and check that the level is up to but does not exceed the MAX. If level is not at the MAX. level, add additional oil. Re-tighten the cap A or C. Important Do not exceed the MAX level on the dipstick. Do not use the engine with the oil level below the MIN. Fig 4.3

Important For safety precautions see Par. 2.4. Before proceeding with operation, read Par. 3.2.2. Place engine on horizontal surface to ensure accurate measurement of filling. Loosen the oil filler cap A. Add the type of oil recommended (Par. 2.4.2). Fig 4.4 Remove the oil dipstick B and check that the level is up to but does not exceed the MAX. If level is not at the MAX level, add additional oil and reinsert the dipstick correctly in the reversing gear seat C. Re-tighten the cap A or C. Important Do not exceed the MAX level on the dipstick. Do not use the engine with the oil level below the MIN. Fig 4.5

Important Before proceeding with operation, read Par. 3.2.2. Place engine on horizontal surface to ensure accurate measurement of filling. Warning An anti-freeze protection liquid (ANTIFREEZE) - mixed with decalcified water - must be used. The freezing point of the refrigerant mixture depends on the amount concentration in water. As well as lowering the freezing point, the antifreeze also raises the boiling point. A 50% mixture is recommended to ensure a general level at protection prevents the formation of rust, galvanic currents and calcium deposits. NOTE: Before proceeding with any operation on the engine, stop it and allow it to cool. Warning Presence of steam pressurized coolant danger of burns. Loosen the cap A and fill the radiator with coolant composed of: 50% ANTIFREEZE and 50% decalcified water. Loosen the screw C, release any air and tighten the screw C (Tightening torque of 8 Nm - Fig. 4.7).NOTE: The MAX filling level for exhaust manifold B is in correspondence of capscrew C, complete the coolant refilling procedure as soon as the coolant starts leaking out of capscrew C (Fig. 4.7). Re-tighten the cap A. After a few minutes of operator, stop the engine and allow the liquid to cool returns to a ambient temperature and check the coolant level again. Fig. 4.6 Fig. 4.7

5

Information about maintenance

This chapter shows all operations described in the Tab. 5.1 and Tab. 5.2. if you have the skills appropriate may be directly carried out by the user. Periodic inspection and maintenance operations must be carried out as indicated in this manual and are the responsability of the user. Failure to comply with these service and maintenance intervals increases the risk of technical damage to the engine. Any non compliance makes the warranty become null and void. In order to prevent personal and property damage read carefully the instructions listed below before proceeding with any operation of the engine. Warning Inspections must be made when the engine is off and cold. Place engine on level sur face to ensure accurate measurement of oil level. Before starting, to avoid spillages of oil make sure that: - the oil dipstick is inserted correctly; - also check that: oil drain plug and oil filler cap are tightened firmly. Important Before proceeding with operation, read Par. 3.2.2. Danger For safety precautions see Chap. 3.

The intervals of preventive maintenance in Tab. 5.1 e Tab. 5.2 refer to the engine operating under normal operating conditions with fuel and oil meeting the recommended specifications. Tab. 5.1 CLEANING AND CHECKING OPERATION DESCRIPTION PERIOD (HOURS) PAR. 10 250 500 5000 Engine oil level 5.3 Coolant level 5.5 Radiator heat-exchange surface (2) 5.6 Rubber hose 5.4 Fuel hose 5.4 Starter Motor (5) -- Tab 5.2 REPLACEMENT OPERATION DESCRIPTION PERIOD (HOURS) PAR. 10 250 500 5000 Engine oil (1) 6.1 Oil filter cartridge (1) 6.2 Fuel filter cartridge (1) 6.3 Water pump belt (3)(5) 6.7 Alternator belt (3)(5) 6.6 Coolant (4)(5) 6.5 Coolant hoses (5)(7) -- Fuel hoses (5)(7) -- Dry air cleaner cartridge (2) 6.8 Water pump impeller 6.4 (1) - In case of low use: 12 months. (2) - The period of time that must elapse before checking the filter element depends on the environment in which the engine operates. The air filter must be cleaned and replaced more frequently under very dusty conditions. (3) - In case of low use: 36 months. (4) - In case of low use: 24 months.(5) - The replacement must be carried out by authorized Lombardini Marine workshops. (7) - The replacement interval is only an indication, it strongly depends from environmental condition and hose status detected during regular visual inspection. (8) - Not supplied by Lombardini Marine.

Important Before proceeding with operation, read Par. 3.2.2. Do not exceed the MAX level on the dipstick. Do not use the engine with the oil level below the MIN. Place engine on horizontal surface to ensure accurate measurement of checking. Loosen the oil filler cap A. Remove the oil dipstick B and check that the level is up to MAX. Pour in recommended oil until reaching the MAX level mark. Reinstall the oil dipstick B completely. Re-tighten the cap A and/or C. Fig 5.1 Fig 5.2

Danger For safety precautions see Chap. 3. The check is carried out by exerting a slight deflection or bending along the pipe and near the hose clamps. Components must be replaced if they have clear signs of cracks, tears, cuts, leaks and do not retain a certain degree of elasticity. Important Before proceeding with operation, read Par. 3.2.2. If hoses are damaged contact an authorized Lombardini Marine workshop. Check that the: Fuel system hoses A are intact. Hoses for the cooling circuit B1, B2, B3 and B4. Vent system pipes C. Fig 5.3

NOTE: Before proceeding with any operation on the engine, stop it and allow it to cool. Important Before proceeding with operation, read Par. 3.2.2. Place engine on horizontal surface to ensure accurate measurement of checking. Danger For safety precautions see Chap. 3. Warning Presence of steam pressurized coolant danger of burns. Start the engine without the radiator cap A. Undo capscrew C and refill the cooled exhaust manifold B until coolant leaks out of capscrew C.NOTE: The MAX filling level for exhaust manifold B is in correspondence of capscrew C, complete the coolant refilling procedure as soon as the coolant starts leaking out of capscrew C. Reinstall the cap A and capscrew C. NOTE: For coolant filling see Par. 4.7. Warning Before starting make sure that the radiator cap and cap, if present, are installed correctly to avoid spillage of liquid or vapour at high temperatures. Fig 5.4 Fig 5.5

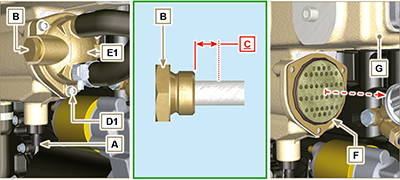

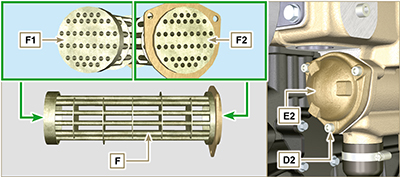

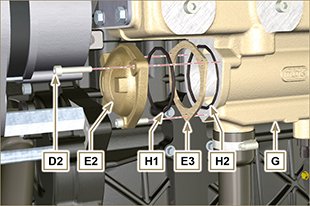

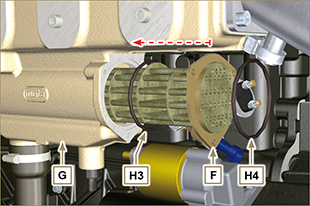

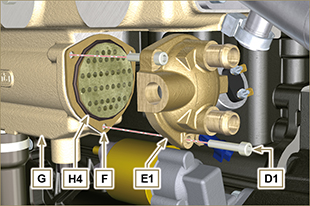

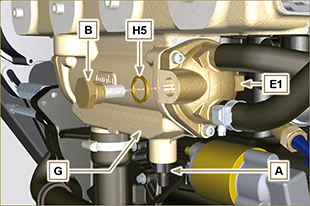

Important Before proceeding with operation, read Par. 3.2.2. Danger For safety precautions see Chap. 3. Warning Protect the starter motor adequately against contact with liquids before starting operations. Slightly undo union A to drain the coolant into an appropriate container and refer to Par. 3.5. Undo capscrew B. Replace component B if value C is below 15 mm. Undo capscrew D1, D2 and remove cap E1, E2. Remove radiator F from cooled manifold G. Perform the cleaning operations, immerse components F, E1, E2 in a solution of distilled water with 10% hydrochloric acid. Make sure that radiator F is free from deposits and dirt of any kind. Make sure that all the holes in surfaces F1, F2 are free from deposits and dirt of any kind. Fig. 5.6 Fig. 5.7 NOTE: if the inside of the pipes on surfaces F1 and F2 (Fig. 5.7) are clogged with deposits even after having been cleaned as per step 6, the pipes must be cleaned using specific mechanical tools. Important Replace all the gaskets. Fasten cap E2 onto manifold G using capscrews D2 inserting flange E3 and also inserting: - gasket H1 between E2 and E3 - gasket H2 between E3 and G. (tightening torque: MIN 5 Nm, MAX 7.5 Nm) Insert gasket H3 in radiator F. Insert radiator F all the way into manifold G. Insert gasket H4 in radiator F. Fasten cap E1 onto manifold G using capscrews D1 (tightening torque: MIN 5 Nm, MAX 7.5 Nm) Clamp capscrew B on cap E1 inserting gasket H5 (tightening torque 30 Nm). Screw union A onto manifold G. Perform the operations described in Par. 6.4. Fig. 5.8 Fig. 5.9 Fig. 5.10 Fig. 5.11

Important If the engines are not to be used for 6 months, they must be protected by carrying out the operations described in Engine storage (up to 6 months) (Par. 5.8). If the engine is still not in use after the first 6 months, it is necessary to carry out a further operation to extend the protection period (more than 6 months) (Par. 5.9). If the engine is not to be used for an extended period, the protective treatment procedure must be repeated within 24 months of the previous one.

Before storing the engine check that: The environments are not humid or exposed to bad weather. Cover the engine with a proper protective sheet against dampness and atmospheric contaminants. The place is not near electric panel. Avoid storing the engine in direct contact with the ground.

Follow the steps described in Par. 5.8. Engine oil replacement (Par. 6.1). Refuel with fuel additives for long storage. With expansion tank: make sure that the coolant is up to the maximum level. Without expansion tank:Follow the steps described in Par. 4.7. Start the engine and keep it idle at minimum speed for 2 minutes. Bring the engine to 3/4 of the maximum speed for 5÷10 minutes. Turn off the engine. Completely empty the fuel tank. Spray SAE 10W-40 on the exhaust and intake manifolds. Seal the exhaust and intake ducts to prevent foreign bodies from entering. When cleaning the engine, if using a pressure washer or steam cleaning device, avoid directing the nozzle on electrical components, cable connections and sealed rings (oil seals etc). If cleaning engine with a pressure washer or steam cleaner, it is important to maintain a minimum distance of at least 200mm between the surface to be washed and the nozzle - avoiding absolutely electrical components such as alternators, starter motors and engine control units (ECU). Treat non-painted parts with protective products. If the engine protection is performed according to the suggestions indicated no corrosion damage should occur.

Remove the protective sheet. Use a cloth soaked in degreasing product to remove the protective treatment from the external parts. Inject lubricating oil (no more than 2 cm3) into the intake ducts. Refill the tank with fresh fuel. Make sure that the oil and the coolant are up to the maximum level. Start the engine and keep it idle at minimum speed for a two about minutes. Bring the engine to 75% of maximum rated speed for 5 to 10 minutes. Stop the engine while the oil is still hot (Par. 6.1), discharge the protective oil in a suitable container. Warning Over time, lubricants and filters lose their properties, so it is important consider whether they need replacing, also based on the criteria described in Tab. 5.2. Replace the filters (air, oil, fuel) with original spare parts. Pour new oil (Par. 4.5) up to the maximum level. Empty the cooling circuit completely and pour in the new coolant up to the maximum level (Par. 6.5).

6

Information about replacements

Danger Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Before proceeding with operation, read Par. 3.2.2 Place engine on level sur face to ensure accurate measurement of oil level. NOTE: Perform this operation with warm engine, to get a better fluidity of the oil and get a full discharge of oil and impurities contained in it. Loosen the oil filler cap A. Remove the oil dipstick B (Fig. 6.3). Remove oil drain plug D from pump E. Start pump E and drain the oil in the engine. Drain oil in an appropriate container (For the exhausted oil disposal, refer toPar. 6.9). Tighten the drain oil plug D (tightening torque at 10 Nm). Perform the operation described in Par. 6.2. Add the type oil recommended (Tab. 2.1 and Tab. 2.2). If the plug A is not accessible, use the oil filler cap C. Fit and remove the oil dipstick B to check the level. Pour in fluid until reaching the MAX level mark. Upon completion, reinstall the oil dipstick B completely. Tighten the cap A or C. Important Do not exceed the MAX level on the dipstick. Do not use the engine with the oil level below the MIN. Fig. 6.1 Fig. 6.2 Fig. 6.3

Important Before proceeding with operation, read Par. 3.2.2 Warning In case of low use replace it 12 months. For disposal of oil filter cartridge refer to Par. 6.9. Unscrew the oil filter A with appropriate wrench. Assembly and tighten the new oil filter cartridge A tightening it with torque wrench B (torque to 15 Nm). Fig 6.4

Important Before proceeding with operation, read Par. 3.2.2 Warning In case of low use replace it 12 months. For disposal of oil filter cartridge and fuel filter refer to Par. 6.9. Procure a suitable container to collect the fuel. Loosen and remove cartridge A. Lubricate the gasket C.Tighten the new cartridge A onto support B (tighten manually). Important Do not fill the new cartridge A with fuel. Turn the key on the control panel to the ON position.The electric pump D sends fuel to the filter B and then the injection pump. Loosen the air bleeding screw F on fuel filter bracket B.The air inside the circuit and the filter will begin to escape from the screw F. Tighten the bleeding screw F (tightening torque of 1.5 Nm) when the fuel begins to flow. Fig 6.5

Danger Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Before proceeding with operation, read Par. 3.2.2 Replace gasket G. Loosen capscrews A and remove cover B. Remove impeller C from pump body D. Grease the new impeller C. Insert the new impeller C onto shaft E. Fasten cover B with capscrews A and washers F and insert gasket G between cover B and pump body D. Fig. 6.6 Fig. 6.7 Fig. 6.8

Danger Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Before proceeding with operation, read Par. 3.2.2. Undo cap A to drain all liquid from the system contained in the engine crankcase ducts into an appropriate container (Par. 3.5). Important Perform the operations described inPar. 5.6 before proceeding. Replace gasket C. Screw cap A onto crankcase B, inserting gasket C (tightening torque 50 Nm). Perform the operations described in Par. 4.7. Fig. 6.9 Fig. 6.10

Danger Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Before proceeding with operation, read Par. 3.2.2. Loosen capscrews A and remove guard B. Loosen hollow stud C and capscrew D. Remove the belt F. Perform the operations from point 2 to 6 of Par. 6.7. Fig. 6.11 Fig. 6.12 Insert the new belt F on pulleys G. Move alternator E in the direction of arrow H, tighten capscrew D followed by hollow stud C (tightening torque at 40 Nm). Check the tension of belt F with a Clavis-type of instrument, positioning it in point P (the value must be 392 N). Fig. 6.13 Secure guard B with capscrews A (tightening torque at 5 Nm). Fig. 6.14

Danger Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Before proceeding with operation, read Par. 3.2.2. Perform the operations from point 1 to 3 of Par. 6.6. Remove belt A. Fig. 6.15 Insert the new belt A onto pulley G1 and start fitting pulley G2 in point B, making sure to channel the internal ribs of the belt into the ducts of pulley G2, as shown in detail B1. Start turning pulley G1 clockwise manually, keeping belt A in position, as shown in detail B1. Continue turning pulley G1 until belt A is completely channelled on pulley G2. Perform operations from point 4 to 7 of Par. 6.6. Fig. 6.16

Danger Disconnect the negative wire (-) from the battery to avroid accidental engine stating. Important Before proceeding with operation, read Par. 3.2.2. Loosen clamp A and remove filter B from manifold A. Fasten the new air cleaner B onto manifold C using clamp A. Fig. 6.17

In case of scrapping, the engine shall be disposed of in appropriate locations, in conformity with the law in force. Before scrapping, it is necessary to separate the rubber or plastic parts from the rest of the components. The parts only composed of plastic material, aluminium and steel can be recycled if collected by the appropriate centers. Waste oil must properly be recycled and disposed of in the correct way to safeguard the environment. According to the laws in force, it is classified as hazardous waste, therefore it must be collected by the appropriate centers.

7

Information about failures

This chapter contains information about the problems that may appear during engine operation with its causes and trouble shooting Tab. 7.2. In some cases, you shall turn off the engine immediately to avoid further damage Tab. 7.1. Tab 7.1 THE ENGINE MUST BE IMMEDIATELY TURNED OFF WHEN: 1 The engine rpms suddenly increase and decrease 2 A sudden and/or unusual noise is heard 3 The colour of the exhaust fumes suddenly darkens 4 The oil pressure indicator light turns on while running Tab 7.2 TROUBLES POSSIBLE CAUSE SOLUTION PAR. The engine does not start Sulphated battery terminals corroded Clean the battery terminals -- Battery voltage too low Recharge the battery or replace it -- Low fuel level Refuel 4.4 Frozen fuel Contact Lombardini Marine authorised workshops -- Clogged fuel filter Replace with a new filter 6.3 Air suction in fuel system Contact Lombardini Marine authorised workshops -- Clogged air filter Replace with a new filter -- Clogged pipes Contact Lombardini Marine authorised workshops -- Open fuse Replace with a new fuse; if the problem persists, contact Lombardini Marine authorised workshops -- Intake or exhaust system clogged Contact Lombardini Marine authorised workshops -- Engine starts but stops Inefficient electrical connections Clean the electrical contacts; if the problem persists, contact Lombardini Marine authorised workshops -- Sulphated battery terminals Clean the battery terminals -- Clogged fuel filter Replace with a new filter and clean the tank 6.3 Clogged fuel pipes Contact Lombardini Marine authorised workshops -- RPM instability at idle speed Clogged fuel pipes Contact Lombardini Marine authorised workshops -- Low idle speed Clogged fuel pipes Contact Lombardini Marine authorised workshops -- Poor quality fuel Clean the tank and refuel with quality fuel 2.5 Blue smoke High oil sump level Replace the engine oil; if the problem persists, contact Lombardini Marine authorised workshops 6.1 Clogged air filter Replace with a new filter 6.8 Excessive fuel consumption Clogged air filter Replace with a new filter 6.8 High oil sump level Replace the engine oil; if the problem persists, contact Lombardini Marine authorised workshops 6.1 Engine lost its initial performance Clogged air filter Replace with a new filter 6.8 Clogged fuel pipes Contact Lombardini Marine authorised workshops -- Cheap fuel Clean the tank and refuel with quality fuel -- High oil sump level Replace the engine oil; if the problem persists, contact Lombardini Marine authorised workshops 6.1 Slow acceleration Clogged fuel filter Replace the fuel filter 6.3 Engine jerking Clogged fuel pipes Contact Lombardini Marine authorised workshops Engine overheats Insufficient coolant level Fill up to the level 5.6 High oil sump level Replace the engine oil; if the problem persists, contact Lombardini Marine authorised workshops 6.1 Clogged radiator Clean the radiator; if the problem persists, contact Lombardini Marine authorised workshops 5.7 In the event that the solutions proposed in Tab. 7.2 do not eliminate the trouble, contact a Lombardini Marine authorized workshop.

Tab. 7.3 shows the errors that can be generated on the control panel. Tab. 7.3 POS. DESCRIPTION Engine oil pressure low High coolant temperature Disabled alternator (with engine rpm < 850 rpm) Maintenance service (*1) Insufficient battery voltage (flashing display with battery < 9 V) Besides visual signals, acoustic errors are also transmitted from the panel.Any errors disappear automatically once the anomaly has been solved.(*1) - A maintenance service does not automatically carry out a reset; it must be reset manually, as follows: Press the E push button until the maintenance service page (Service h) is displayed on the screen D. Simultaneously press push buttons E and F for 10 secs. for screen D to reset the hours until the next maintenance. Fig 7.1

8

Information about warranty

9

Glossary

Zinc anode and radiator check

Important Important

|

|

|

Fig. 5.7 |

|

NOTE: if the inside of the pipes on surfaces F1 and F2 (Fig. 5.7) are clogged with deposits even after having been cleaned as per step 6, the pipes must be cleaned using specific mechanical tools.

|

Fig. 5.8

Fig. 5.9 |

|

Fig. 5.10 |

Fig. 5.11 |

Danger

Danger Warning

Warning

Loading

Loading