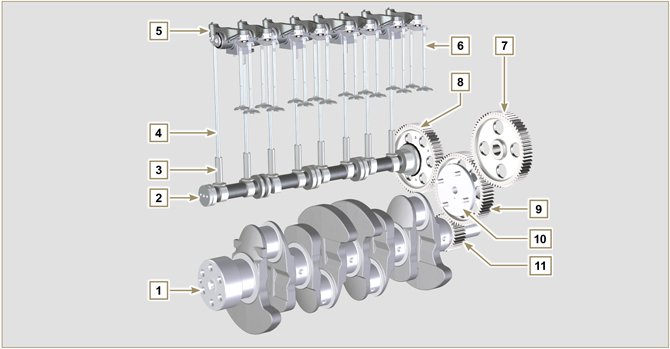

Timing system and tappets

|

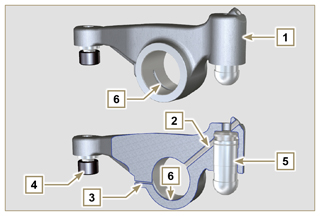

The timing system is equipped with hydraulic tappets that automatically recover the operation of the rocker rods assembly. 2.16.1 Components identification  Fig 2.52 |

|||||||||||||||||||||||||||||||

|

Tab 2.35

|

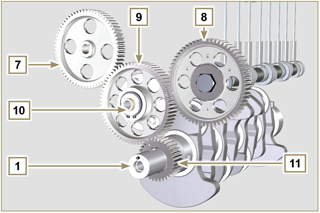

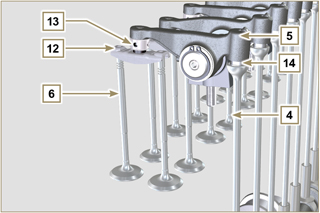

Fig 2.53  Fig 2.54 |

||||||||||||||||||||||||||||||

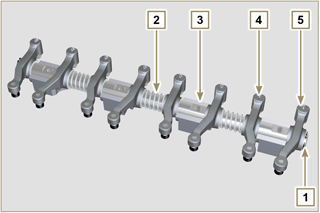

| 2.16.2 Rocker arm pin Tab 2.37

|

Fig 2.56 |

||||||||||||||||||||||||||||||

| 2.16.3 Rocker arms Tab 2.38

|

Fig 2.57 |

||||||||||||||||||||||||||||||

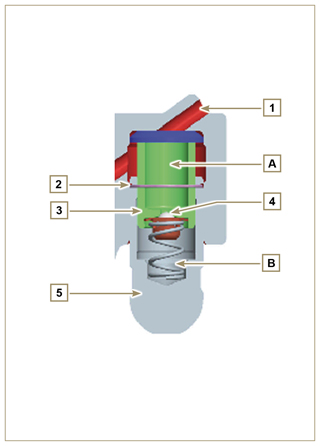

| 2.16.4 Hydraulic tappets Tab 2.39

2.16.4.1 Hydraulic tappet operation The operating principle of the hydraulic tappet is based on the incompressibility of the liquids and on controlled leakage. The oil under pressure enters the tappet chamber A, providing a constant supply of oil in the low-pressure chamber. Through the non-return valve, 4 the oil can only access the high-pressure chamber B and exit via the clearance between the piston 3 and the tappet body 5 (controlled leakage). The chamber B is filled when the rocker arm is on the base radius of the cam and the spring 6 keeps the piston 3 against the valve stem, thus eliminating any system play. Thanks to the spring extension, the tappet "extends", creating a small depression in the chamber B, making the non-return valve 4 open, and allowing the oil in the chamber A to pass to chamber B, restoring the proper amount of oil required to eliminate any play in the valves. |

Fig 2.58 |

||||||||||||||||||||||||||||||

|

2.16.4.2 Difficult operating conditions

Anyway the duration of ticking Anyway the duration of ticking sound must be MAX 30 seconds. If not, the problem is surely due to the poor quality of the oil, wear or impurities that, transported by the oil, can infiltrate between the ball valve and its seat inside the piston, compromising the operation of the tappet itself; In these cases, the only solution is to replace the oil or hydraulic tappets. |

Loading

Loading