Important Important

- Before proceeding with operation, read Par. 3.3.2.

- Replace the high pressure pipes after two disassemblies.

- Always replace the gaskets after each disassembly.

- Handle the components as described in Par. 2.17.

- Please refer to Par. 1.3 in order to see the operating references during disassemble and assemble procedures.

- When repaired, RSN-A injectors must be certified by a Stanadyne centre to check their correct operation - check the type of engine mounted injectors on the spare parts list (RSN-A is specified in the description).

|

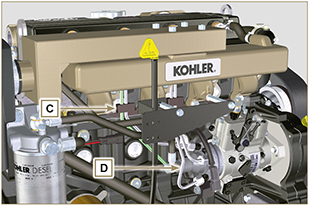

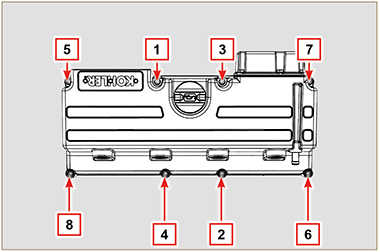

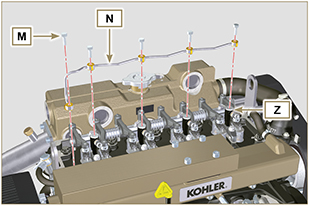

Fig 6.1 |

|

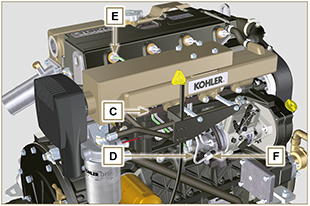

6.1.1injection fuel pump disassembly (injection pump/injectors)

- Remove the retainers C for the hoses D.

|

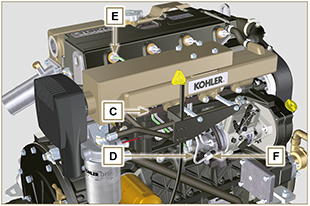

Fig 6.2 |

- Undo the nuts F.

- Undo the nuts E.

- Remove the tube D.

|

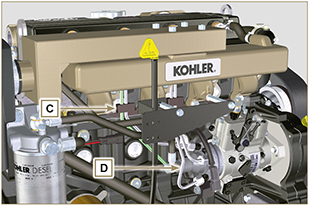

Fig 6.3 |

|

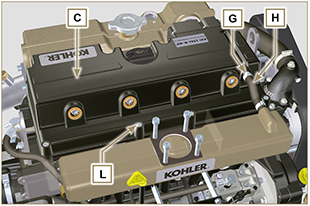

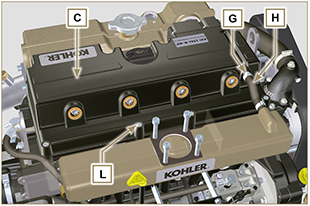

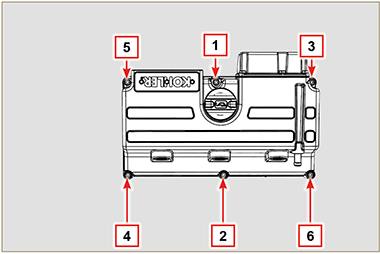

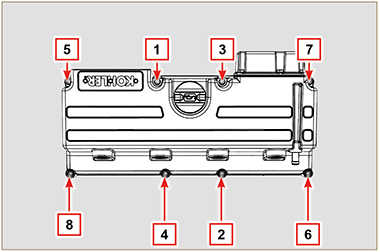

6.1.2 Rocker arms cover disassembly

- Loosen clamp G and disconnect hose H

- Undo the screws L and remove the rocker arm cap C.

|

Fig 6.4 |

|

6.1.3 Fuel return pipes disassembly

- Undo the screws M and remove hose N.

|

Fig 6.5 |

|

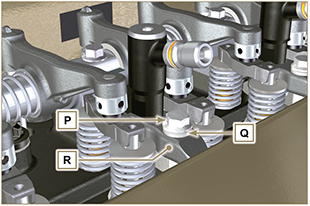

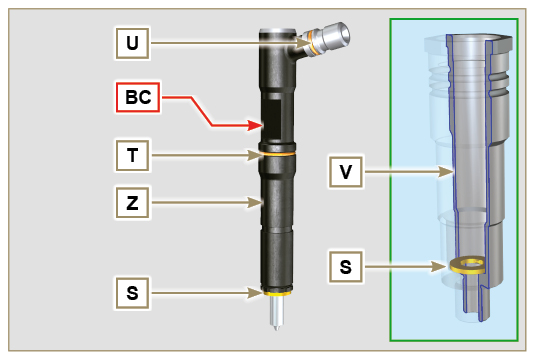

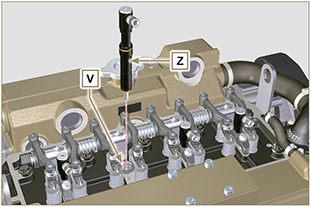

6.1.4 Injectors disassembly

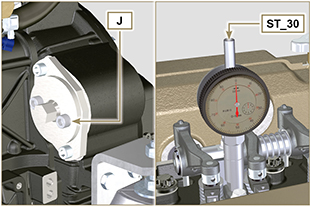

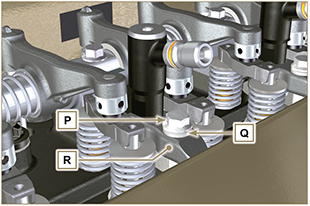

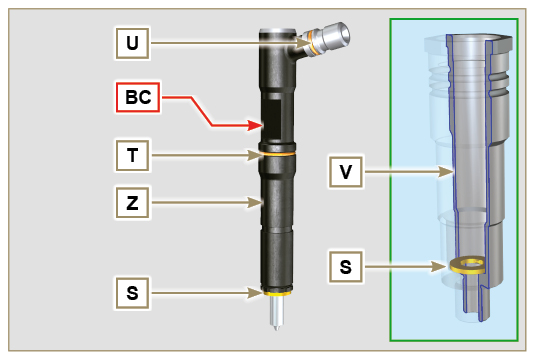

- Undo the screw P and remove washer Q and bracket R.

- Remove the injector Z.

NOTE: Should you be unable to remove the injector (acting only on point BC), use an open-ended spanner (11 mm), by applying small rotations to unblock the component.

- Seal all injection component unions as illustrated in Par. 2.9.7.

NOTE: If the washer S is not found on the injector Z, recover it from inside the sleeve V.

|

Fig 6.6

Fig 6.7

|

6.1.5 Injection pump disassembly

Important Important

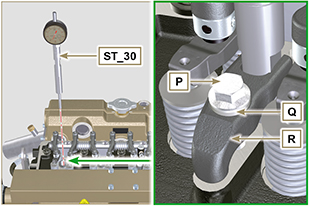

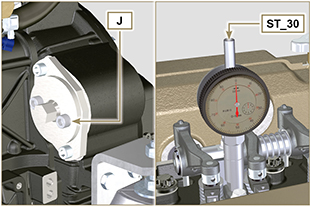

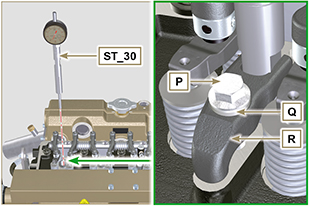

- Insert the tool ST_30 into the injector N°1 and fix it with the fixing brace R of the injector, capscrew P and washer Q.

NOTE: Do not tighten the capscrew P.

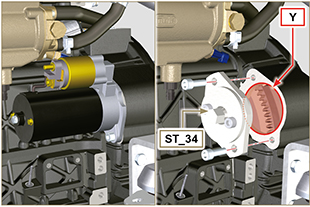

- Disassemble the starter motor.

- Mount the tool ST_34 in the seat of the starter motor Y and fit it with the two starter motor fixing screws.

-

Rotate the crankshaft clockwise (as seen from the timing system side - Ref. A Par. 1.3) by means of tool ST_34, compressing the piston of cylinder N° 1 (the valves of piston N° 1 must all be closed).

Fig 6.9

Tab. 6.1

| PUMP CODE |

PISTON

LOWERING (mm) |

ADVANCE

α

|

| ED0065900040-S |

1,695 |

13° |

| ED0065905050-S |

1,695 |

13° |

| ED0065905110-S |

1,963 |

14° |

| ED0065905150-S |

1,695 |

13° |

| ED0065905160-S |

1,695 |

13° |

| ED0065905170-S |

1,695 |

13° |

| ED0065905180-S |

1,695 |

13° |

| ED0065905350-S |

1,963 |

14° |

| ED0065905380-S |

3,228 |

18° |

| ED0065905410-S |

2,558 |

16° |

| ED0065905470-S |

1,695 |

13° |

| ED0065905500-S |

1,695 |

13° |

| ED0065905510-S |

1,695 |

13° |

| ED0065905540-S |

1,006 |

10° |

| ED0065905640-S |

1,695 |

13° |

| ED0065905650-S |

1,695 |

13° |

| ED0065905660-S |

1,695 |

13° |

| ED0065905670-S |

1,695 |

13° |

| ED0065905680-S |

1,695 |

13° |

|

Fig 6.8

Fig 6.10

|

|

5. Find the TDC through tool ST_30, then bring the dial gauge indicator to 0.

6. Having identified the value to lower the piston, rotate the crankshaft anti-clockwise by going beyond the value described in Tab. 6.1, once again, rotate the crankshaft clockwise, stopping at the correct advance value by using tool ST_30.

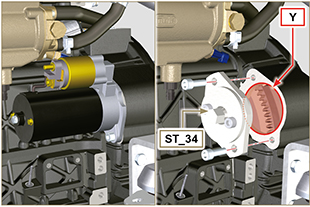

7. Lock the ST_34 tool through J screws and ensure that the crankshaft does not rotate, which would alter the correct advance value. If this happens, repeat the instructions described in points 4, 5, 6, 7 and 8.

NOTE: The value indicated in Tab. 6.1 must be reached by rotating the shaft with the piston in compression phase. Use the ST_34 tool to totate the crankshaft.

|

Fig 6.11

Fig 6.12

|

|

8. Lock the ST_34 tool through J screws and ensure that the crankshaft does not rotate, which would alter the correct advance value. If this happens, repeat the instructions described in points 4, 5, 6, 7 and 8.

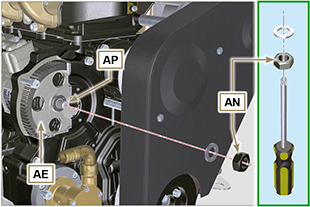

9. Undo the screws AC and remove the oil filling flange AD.

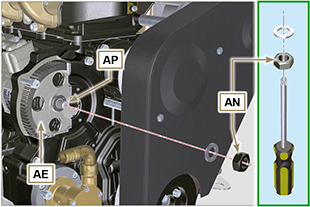

10. Undo and remove the nut AN fixing the injection pump control gear AE.

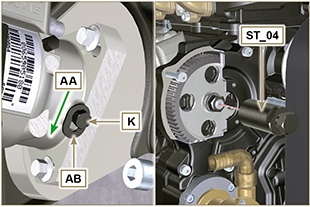

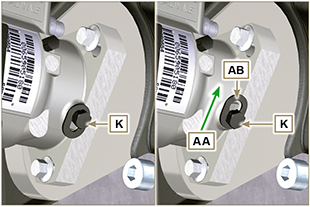

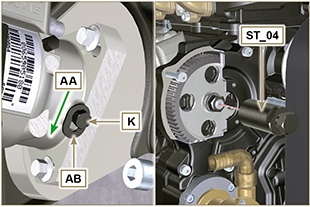

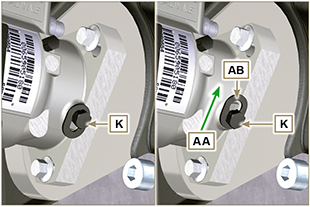

11. Undo the capscrew K and shift the slotted plate AB in the direction of arrow AA.

12. Tighten screw K to block the pump (tightening torque to 12 Nm).

Important Important

- After removing the nut AN, ensure that the correct advance value has remained unchanged on ST_30.

- Be careful that the nut AN does not fall into the timing cover.

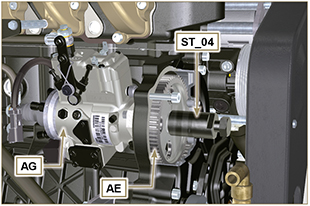

13. Screw the tool ST_04 on the gear AE.

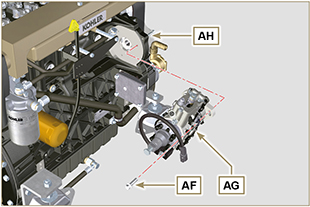

14. Loosen the screws AF.

|

Fig 6.13

Fig 6.14

|

|

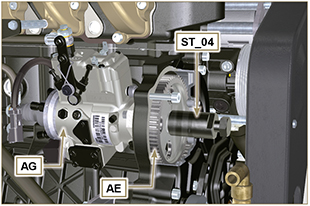

15. Tighten the screw of tool ST_04 to disconnect the injection pump AG from the high pressure pump control gear AE.

16. Undo the screws AF and extract the injection pump AG.

17. Undo and remove the tool ST_04.

|

Fig 6.15

|

|

6.1.6 Injection pump assembly

Warning Warning

- Before assembling the new pump AG, make sure that plate AB can move freely and that fastening capscrews K are not loose (the pump sold as a spare part is supplied with the cylinder injection timing blocked N° 1).

- Ensure that the coupling surfaces on shaft AP and gear AE are free from impurities and lubrication residues.

- Remove the guard cap only when the pipes are reconnected.

- Do not remove the tool ST_30.

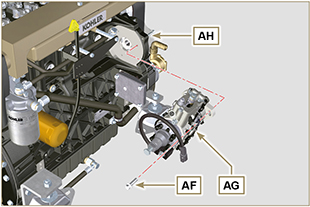

1. Mount the injection pump AG, inserting the shaft AP in the gear AE.

Important Important

- Always change screws AF with new ones or apply Loctite 270 to the threads.

2. Clamp the screws AF on the crankcase AH (tightening torque at 25 Nm).

3. Ensure that the correct advance value has remained unchanged, tighten nut AN on shaft AP (as shown in Fig.6.17, is allowed the aid of a screwdriver to guide the nut AN on the shaft AP in order to avoid the fall of it into the timing cover AQ - tightening torque at 70 Nm).

|

Fig 6.16

Fig. 6.17

|

|

4. Undo the capscrew K and shift the slotted plate AB in the direction of arrow AA.

5. Tighten screw K (tightening torque to 5.5 Nm). The injection pump is unlocked.

6. Remove the tool ST_30 and ST_34.

|

Fig 6.18

|

|

NOTE: Always replace the gasket AJ after each assembly.

7. Position the gasket AJ in the set on the flange AD.

8. Fix the flange AD on the crankcase AQ with the screws AC (tightening torque at 10 Nm).

|

Fig 6.19

|

|

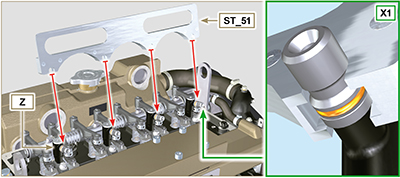

6.1.7 Injector assembly

Important Important

- To prevent damaging the injection system, the protection caps (Par. 2.9.7) must be removed during assembly.

- Lubricate the gaskets U, T, S and fit them on the injector Z.

|

Fig 6.20

|

|

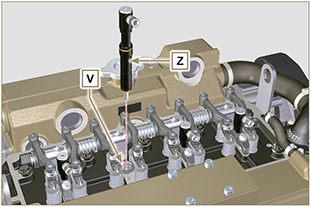

2. Fit the injector Z in the sleeve V.

|

Fig 6.21

|

|

3. Assemble the parts P, Q, R and fit the parts so assembled on the injector Z.

|

Fig 6.22

|

|

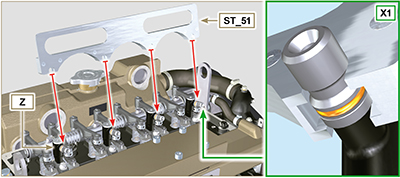

4. Insert tool ST_51 on the injectors junctions Z (detail X1).

5. Tighten the screw P (tightening torque to 20 Nm)

|

Fig 6.23

|

|

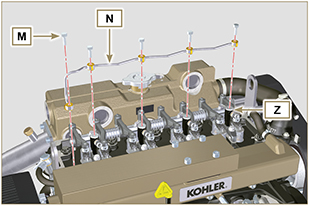

6.1.8 Assembly of the injector return pipes

- Position the tube N on the injectors Z, and tighten screws M (tightening torque to 14 Nm).

|

Fig 6.24

|

|

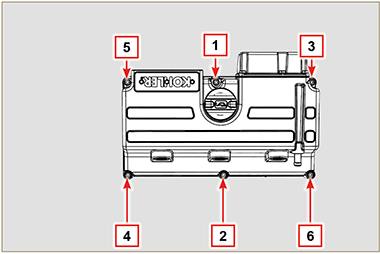

6.1.9 Assembly Rocker arm cover

Important Important

- The gasket AM between the rocker arm cover and the cylinder head must always be replaced every time it is disassembled.

- Position the two guide pins ST_17 before mounting the rocker arm cover.

- Position the gasket AM on the head AL respecting the fastening screw holes L.

- Attach the rocker arm cover C on the head AL with the screw L adhering to the tightening sequence shown in Fig. 6.27 (KDI 1903 M) or Fig. 6.28 (KDI 2504 M) (tightening torque to 10 Nm).

- Connect pipe H and tighten the clamp G.

Important Important

- Always replace the gaskets AK after each disassembly (ST_36).

|

Fig 6.25

Fig 6.26

Fig 6.27

Fig 6.28

|

|

6.1.10 Installation of the fuel injector pipes (pump injector/injectors)

- Position pipes D on the injectors and on the injector pump.

Important Important

- Tighten the nuts E and F manually, without clamping them.

2. Tighten the nuts E ed F (tightening torque at 25 Nm).

3. Reinstall the retainers C of the hoses D.

|

Fig 6.29

|

Important

Important

Important

Important Important

Important Important

Important Important

Important Important

Important Important

Important

Important

Important

Loading

Loading